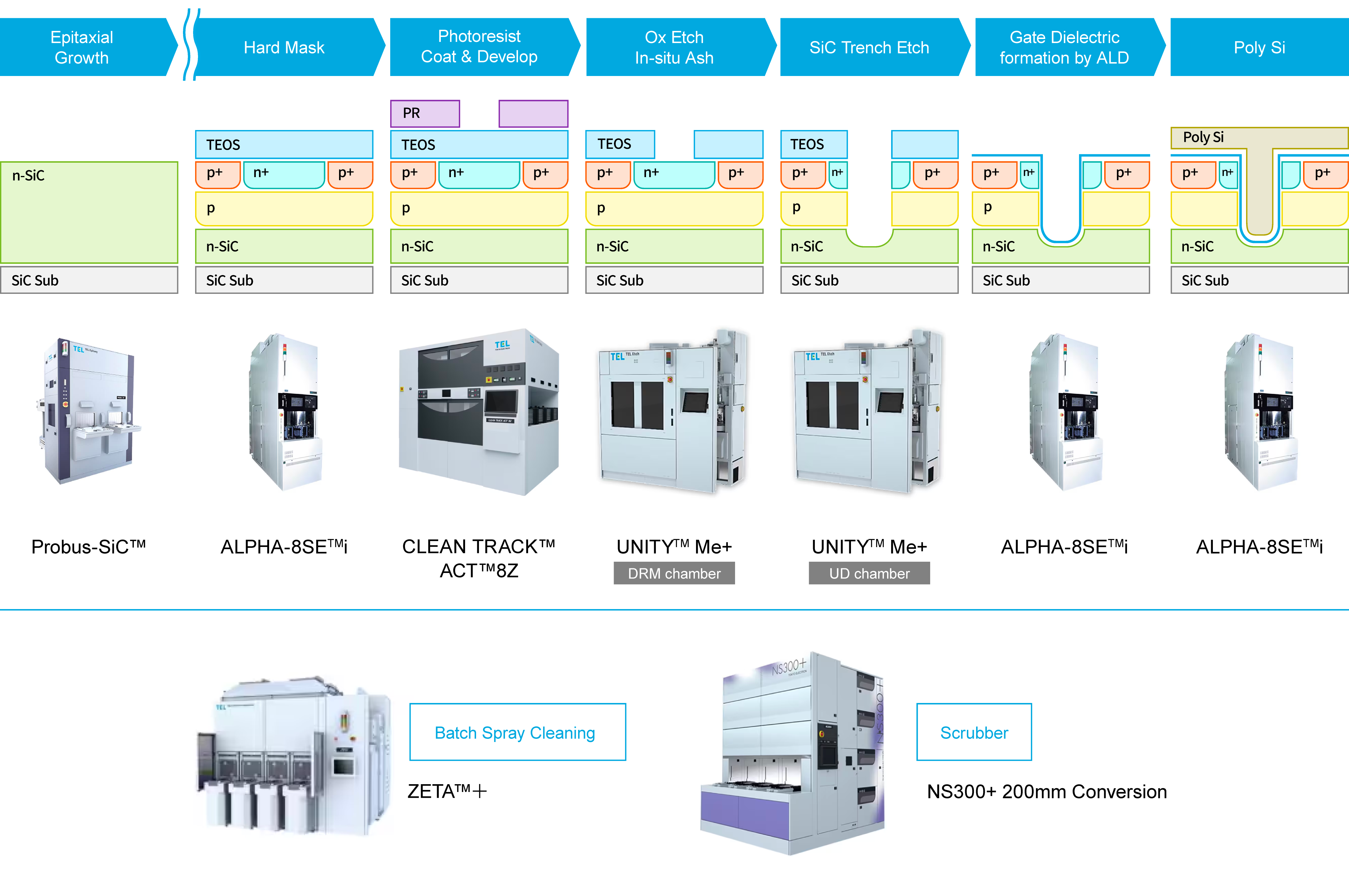

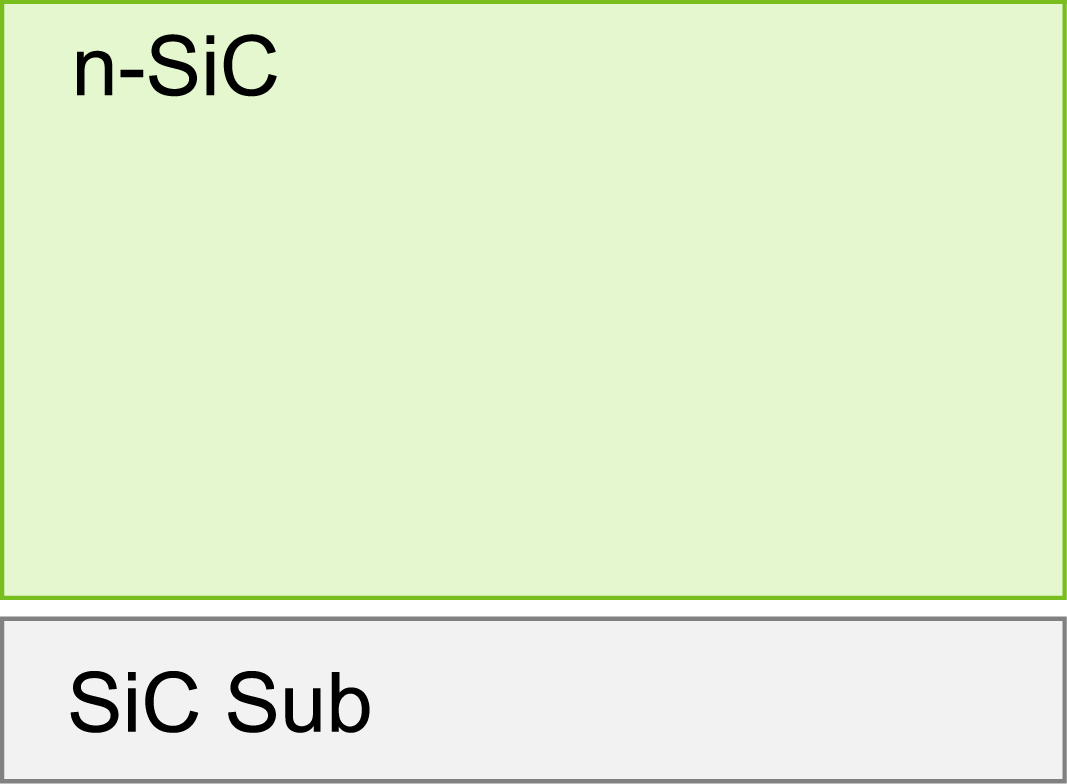

Epitaxial Growth

Probus-SiC™

Epitaxial reactor to grow SiC on 75-150mm substrates used in SiC power semiconductor devices. Incorporating state-of-the-art technologies such as high temperature control under vacuum achieves excellent uniformity in thickness and dopant concentration.

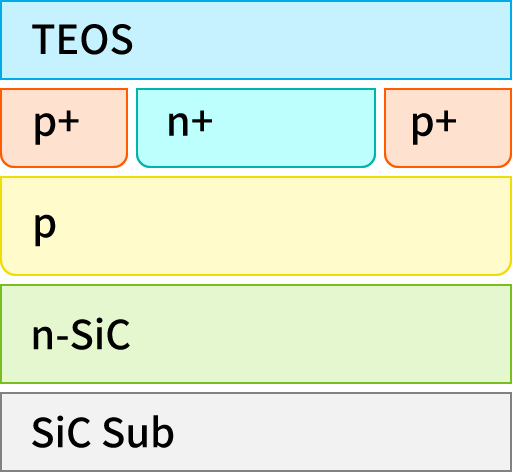

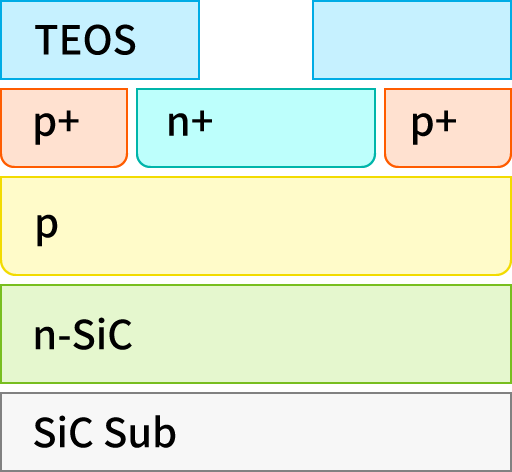

Hard Mask

ALPHA-8SE™i

Batch thermal processing and deposition system for wafers up to 200mm. In addition to improved functionality and ease of operation for stable and continuous availability, the system features conformity with international safety standards.

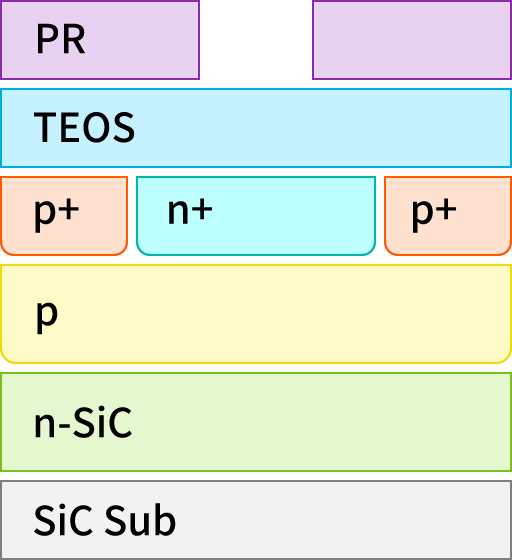

Photoresist Coat & Develop

CLEAN TRACK™ ACT™8Z

The coater/developer for 75-200mm wafers is capable of handling diverse substrates (including thin/thick substrates of Si, GaAs, GaN, SiC, etc.) as well as SOD coating.

Ox Etch In-situ Ash

UNITY™ Me+ / DRM chamber

Plasma etch system for 100-200mm wafers. The system delivers superior cost-performance ratio in production lines and has achieved excellent productivity and reliability.

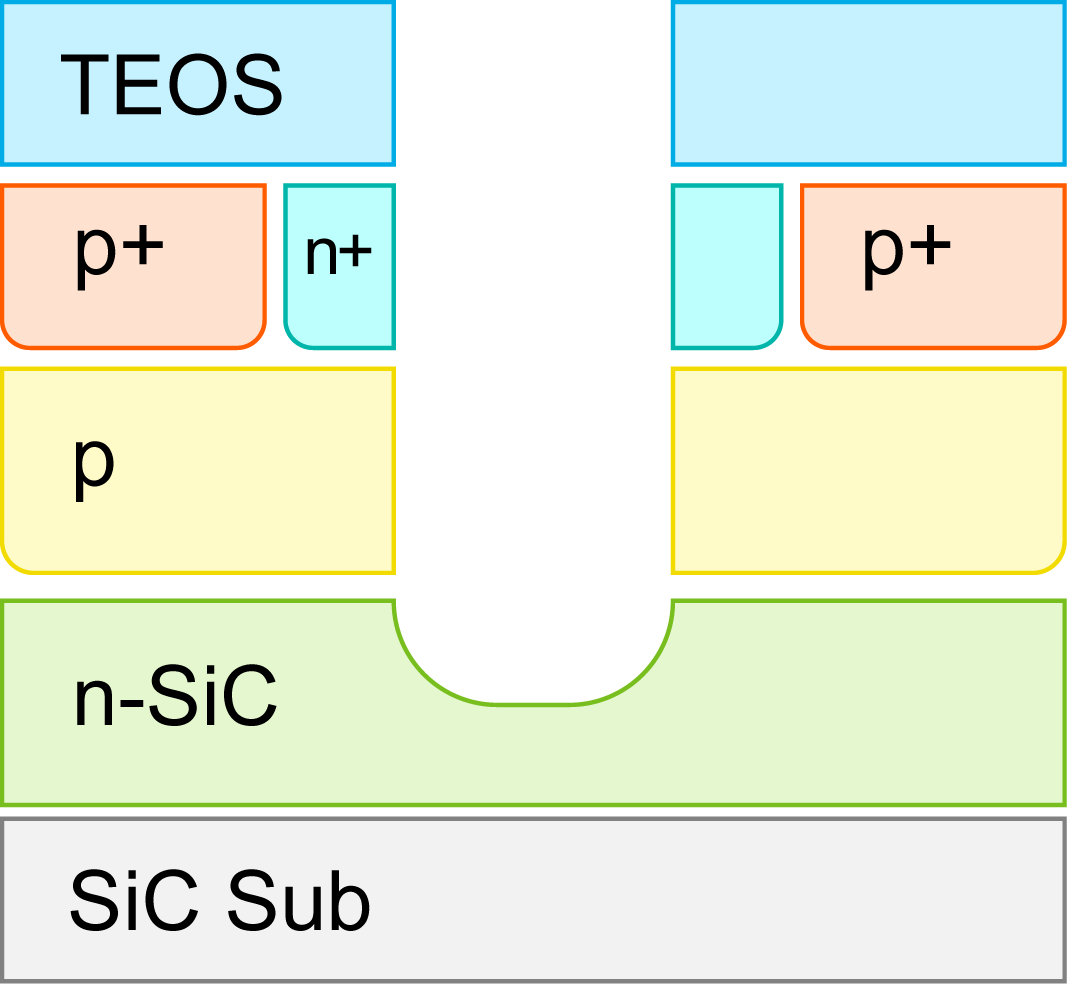

SiC Trench Etch

UNITY™ Me+ / UD chamber

Plasma etch system for 100-200mm wafers. The system delivers superior cost-performance ratio in production lines and has achieved excellent productivity and reliability.

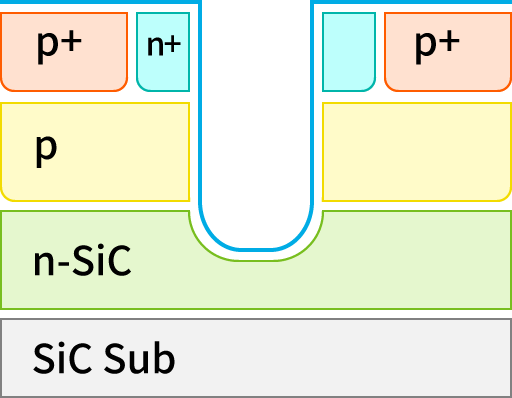

Gate Dielectric formation by ALD

ALPHA-8SE™i

Batch thermal processing and deposition system for wafers up to 200mm. In addition to improved functionality and ease of operation for stable and continuous availability, the system features conformity with international safety standards.

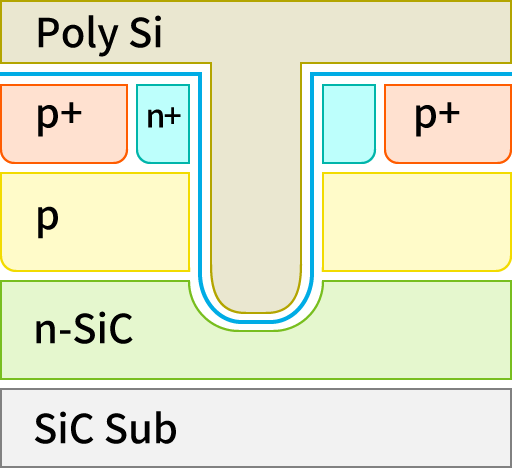

Poly Si

ALPHA-8SE™i

Batch thermal processing and deposition system for wafers up to 200mm. In addition to improved functionality and ease of operation for stable and continuous availability, the system features conformity with international safety standards.

Batch Spray Cleaning

ZETA™+

Fully automated batch spray cleaning system for 300/200mm wafers. The system accommodates FOUPs and SMIF pods that support a clean local environment (minienvironment) optimized for wafer transfers. A more cost-efficient semi-automated version is also available.

Scrubber

NS300+ 200mm Conversion

Scrubber system for 200/150mm wafers. Adopting the cleaning process technologies developed for next-generation 300mm devices, the system offers high reliability and productivity.