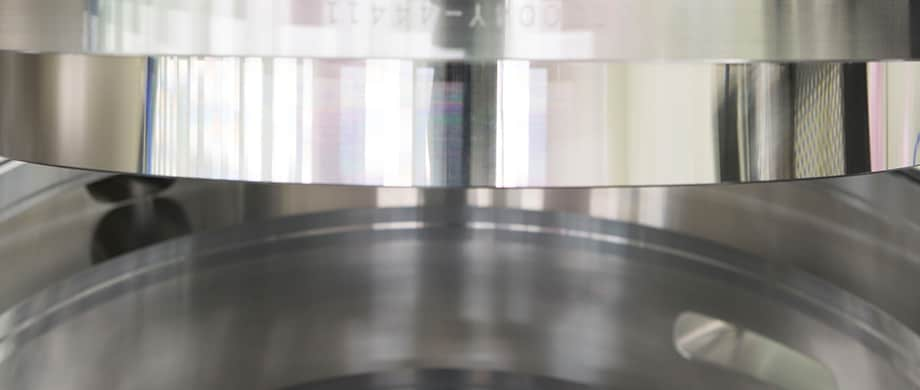

Etch UNITY™ Series

The long-selling etch system has been receiving a lot of attention from the SiC market

The UNITY™ achieves excellent cost performance for plasma etch process within 200mm wafer, which provides exceptional reliability and productivity. Recent years, the system has a great deal and favorable approval through demonstration of high performance Si/SiC trench etch process for leading-edge power devices manufacturing.

UNITY™ Me+ is a successor to the UNITY™ Me dry etch platform that has received high acclaim for 200mm or smaller wafer processing. The renewal of UNITY™ Me in 2021 has significantly extended the support life for the product. The system can be configured with DRM and SCCM™ chambers for SiO2/SiN etch as well as chambers for Si/SiC trench etch. The system supports 100/150/200mm wafer sizes and has a track record of processing Si wafers as well as LT, LN, and other compound wafers. TEL uses an in-house demo tool to evaluate to solve customers’ process issues and achieve the required performance.

Product comparison

|

|

||

| Chamber | SCCM™ | DRM | UD |

| Wafer size (mm) |

200 | 100,150,200 | 100,150,200 |

| Availability | New, Certified used | New, Certified used | |

| Number of chambers | 1-4 | 1-4 | |

| Process | Ox, SiN, HM, EB, Contact, Via, Trench, SAC, Spacer, DD |

Trench, EB, TSV | |

| Substrates | Si, glass, SiC, sapphire, LN, LT, AlTic | Si, SiC, Glass | |

| Safety | S2, CE, ROW | S2, CE, ROW | |

| Additional sizes w/wafer holder (mm) | square | 75, square | N/A |

UNITY and SCCM are is a registered trademarks or trademarks of Tokyo Electron Group in Japan and/or other countries.