Supply Chain Management

Principles and System of Supply Chain Management

To build a supply chain that is sound and sustainable, Tokyo Electron has formulated a procurement policy based on the laws, regulations and social norms of each country, as well as the RBA Code of Conduct*, and together with its suppliers, is implementing activities based on this policy.

To identify issues in the supply chain from a variety of perspectives, we also value ongoing communication with diverse suppliers, including materials suppliers that handle parts and raw materials, staffing suppliers that provide services and logistics suppliers that handle physical distribution operations. Any issues which are identified are shared among the relevant departments which then work on improvement measures, under the supervision of the CEO. We will continue striving to create value across the supply chain by working to build relationships of trust with our suppliers, who support our business as partners, and by working together to deploy our operations in compliance with global standards.

The high-value manufacturing that the Tokyo Electron Group strives for is based on the functions of all materials and components that make up the products and the pursuit of high quality. We value communications with suppliers and seek to grow manufacturing on a global scale with our suppliers based on ongoing trusting relationships.

May 1, 2010 Established

- Compliance with Applicable Laws, Social Norms, and the RBA Code of Conduct

- We engage in procurement activities based on business ethics and with integrity, in compliance with the laws, regulations, and social norms of each country as well as the RBA Code of Conduct.*

The RBA Code of Conduct: Responsible Business Alliance Code of Conduct

https://www.responsiblebusiness.org/code-of-conduct/

A code of conduct drawn up by the RBA. The RBA Code of Conduct establishes standards to ensure that working conditions are safe, that workers are treated with respect and dignity, and that business operations are environmentally responsible and conducted ethically. - Priority on the Environment

- We conduct procurement with full consideration for reduction of environmental impact and protection of the global environment.

- Fair Business Practices

- We continuously seek high-value technologies and create broad opportunities for their business transactions based on the precondition of open competition.

- Partnership

- We prioritize relationships of trust based on mutual understanding with suppliers and conduct activities in the pursuit of mutual continuous growth.

- Information Management

- We properly manage the confidential information of suppliers that we obtain in the course of business

May 1, 2010 Established

September 1, 2024 Revised

The Tokyo Electron Group strives to comply with our Code of Ethics and the RBA Code of Conduct* to contribute to the development of society. We request that our suppliers understand the purpose of these policies and implement them and that their suppliers are also asked to understand and implement these policies.

We aim for sound and sustainable growth together with our suppliers.

- Compliance with Applicable Laws, Social Norms, and the RBA Code of Conduct

We request our suppliers to comply with the applicable laws and social norms in the countries and regions where they engage in business, as well as the RBA Code of Conduct. Please observe the following items in particular.- Prohibition of child labor, forced labor and labor involving debt bondage

- Management of appropriate working hours, breaks, holidays and leaves

- Appropriate payment of wages

- Respect for fundamental human rights, beginning with the prohibition of discrimination and inhumane treatment

- Thorough implementation of business ethics, beginning with the protection of intellectual property rights and the prohibition of false reports, falsification of records, bribery and conflicts of interest

- Compliance with export/import-related laws and regulations

- Prohibition of involvement with antisocial forces

The RBA Code of Conduct: Responsible Business Alliance Code of Conduct

https://www.responsiblebusiness.org/code-of-conduct/

- Considerations of Human Rights and Working Conditions

-

The Group promotes activities based on the Tokyo Electron Group Human Rights Policy. We request that our suppliers respect human rights and create a safe and healthy work environments in their business activities as well, based on their understanding of our Group’s Human Rights Policy.

Tokyo Electron Group Human Rights Policy - Response to the Responsible Procurement of Minerals

-

The Group sees our efforts with regard to the responsible procurement of minerals as part of our corporate social responsibility and promotes all efforts to eliminate any use of raw materials that utilize minerals which have been mined or extracted by illegal methods as well as components or parts that contain such minerals. To this end, we are implementing measures in accordance with the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas. We request that our suppliers understand the situations pertaining to the procurement of minerals and cooperate in the survey for the responsible procurement of minerals.

- Environmentally Conscious Activities

-

In accordance with our Green Procurement Guidelines, we request that, together with the acquisition of ISO 14001 and the development of a structure for environmental conservation, suppliers also actively engage in the utilization and manufacturing of parts and materials that reduce environmental impact and that consider environmental conservation, the conservation of resources and the reduction of greenhouse gas emissions, and in addition, that they strive for biodiversity and forest conservation.

- Management System

-

We request that management systems are developed and continuously improved, including systems related to safety, health, the environment, product quality and labor, in accordance with the corporate procurement agreement or any specific agreements or arrangements with the Group.

- Technical Skills

-

We request that suppliers always strive for improved technical skills and technological innovations.

- Quality

-

We request that suppliers provide high-quality products and services which meet the specifications required by the Group by means of building quality during the design phase and strengthening change control.

- Supply, and Provide Systems

-

We request that suppliers provide a stable and flexible supply of products and services to deal with huge volatility in demand. Also, we request that suppliers prepare precautionary steps and continuity plans to reduce risks in the event of unforeseen situation such as disaster. In addition, we conduct BCP assessments on target suppliers and ask for their cooperation in these activities.

- Price

-

We request that products and services are offered at market-competitive and reasonable prices, and that continuous effort is made to reduce costs.

- Business Management

-

We request that sound and stable business management be implemented for the continuation of our business transactions. We also request that necessary financial and company information is disclosed.

- Information Security

-

In accordance with our Information Security Standards for Partners and Affiliates, we request that suppliers put a system in place that deals with the leaking of confidential information and cyberattacks, and construct an information security environment that appropriately manages and utilizes information. We also request for your cooperation in ensuring the security of our products.

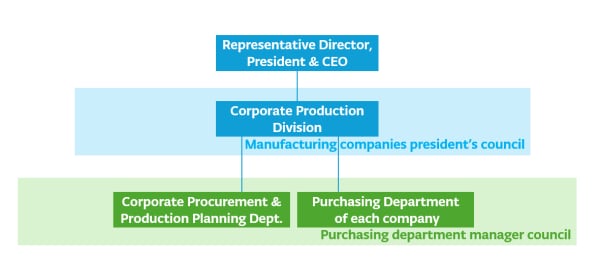

To maintain a robust supply chain capable of supporting streamlined product manufacturing, We have instituted a procurement policy and established a system for administering fair procurement practices based on mutual trust with suppliers. Under the Representative Director and President as the top of the procurement system, the manufacturing companies presidents’ council and the purchasing department manager council are convened to share information on various procurement issues. The council also serves as a venue to address current problems and discuss approaches to improve partnership with suppliers.

Sustainability Operations

Initiatives with Suppliers

To promote quality improvement of the Tokyo Electron Group and implement sustainability in our supply chain, it is essential to build strong partnerships with diverse suppliers, including materials suppliers that handle parts and raw materials, staffing suppliers that provide services, and logistics suppliers that handle physical distribution operations.

Before starting business with new suppliers, a Supplier Total Quality Assessment (STQA)-our Group’s in-house assessment system-is conducted via self-assessment to confirm the state of their product quality, costs, and information security. The assessment also includes CSR issues, including human rights, ethics, safety, and the environment. In addition, we conduct on-site audits to check quality, and if any risks are found, we explain to the supplier the problems and our expectations for the level of quality we require. We also conduct screening using STQA for new suppliers in fiscal year 2025.

For quality, we conduct on-site audits and if any risks are found, we explain to the supplier the defects and our expectations for the level of quality that we require. After the supplier understands the issues, we ask that they plan and implement improvement measures. We also offer continual support to suppliers until all necessary improvements have been made.

After we begin a business relationship, we also conduct on-site audits once every three years at suppliers who manufacture important components and at suppliers where quality issues have been detected.

Furthermore, in order to build a sound and sustainable supply chain, we request that suppliers cooperate with various assessments regarding sustainability, security, and the environment in accordance with our Procurement Policy - Supplement: Requests to Our Suppliers. We continuously implement these assessments and, if no improvement is observed or if risk has increased significantly to a level that could seriously impact business continuity, we discuss and consider whether to continue the business relationship and provide support for improvement activities.

Sustainability Assessment

We identify impacts to the business and various risks, and conduct screening of suppliers that require prioritized and continuous confirmation of their sustainability implementation states. For suppliers selected through screening, we conduct sustainability assessments.

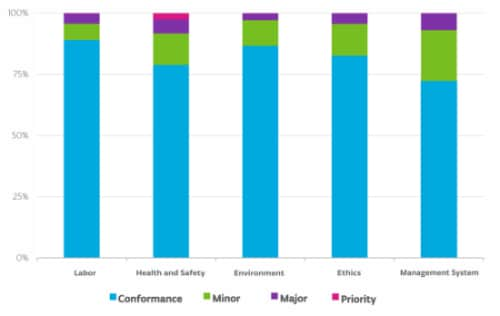

These assessments were launched in fiscal year 2014 for materials suppliers*¹ and expanded in fiscal year 2019 to include staffing*² and logistics*³ suppliers. Since then, we have conducted the TEL Supply Chain Sustainability Assessment (TSSA) annually, based on the RBA audit standards, in the areas of labor, health and safety, environment, and ethics.

We provide feedback on the assessment results to all suppliers who cooperated with the assessment and ask them to carry out any improvement activities required.

Materials suppliers: Suppliers accounting for more than 80% of our procurement spend (85% from fiscal year 2023)

Staffing suppliers: 100% of employment agencies and contracting companies (internal contractors)

Logistics suppliers: 100% of customs-related operators

Supply Chain Sustainability Process

Annual Sustainability Goals and Results for Supply Chain Management

| Target | Fiscal Year 2025 Performance | Future Initiatives |

|---|---|---|

|

|

|

In fiscal year 2024, we conducted TSSA for 704 suppliers that require prioritized and continuous monitoring of sustainability initiatives and received responses from all companies. The assessment results revealed two suppliers with actual/potential risks that needed to be improved with priority, and we have requested that they carry out corrective actions. In fiscal year 2025, we individually checked the implementation status and corrective action plans with 55 suppliers, conducting monitoring while supporting their corrective actions. For the item “worker-paid recruitment and employment related fees,” which falls under the area of forced labor, we confirmed details through engagement with 12 suppliers whose responses raised human rights concerns. As a result of these engagements, some suppliers where risks were confirmed undertook corrective measures, such as making changes to internal operations and documentations to prevent occurrence, after deepened their understanding of the issues and the necessity of corrective measures.

As of the end of fiscal year 2025, of the 137 corrective items planned at 55 suppliers, we confirmed completion of 64 items. Because some corrective items require medium-term efforts to complete, we will continue to work with our suppliers and monitor progress in fiscal year 2026.

Results of Supply Chain Sustainability Assessments Implemented in FY 2024

| Number of suppliers applicable for assessments | 704 |

|---|---|

| Assessment response rate | 100% |

| Number of suppliers confirmed to have risks that needed to be improved with priority | 2 |

| Number of suppliers requested to carry out non-conformance activities for risks | 2 |

| Number of suppliers receiving support and monitoring for corrective actions | 55 |

We also conduct online briefings for suppliers regarding the results of each year's TSSA. In addition to explaining the latest results and the points of corrective actions for each area, we request that suppliers work on non-conformances. Approximately 780 supplier representatives participated in the briefing session held in April 2025, where we explained our Group’s supply chain initiatives and surveys, and requested cooperation in future initiatives. In fiscal year 2026, we are revising the survey questions to align with the latest version of the RBA Code of Conduct, adding questions related to human rights and country- or business-specific risks, and rolling out the survey to 714 suppliers.

Online briefing session

Ongoing Efforts with Suppliers

Example initiative

Tokyo Electron Technology Solutions (Tohoku Office) conducts activities to prevent quality issues jointly with suppliers. By implementing STQA for suppliers, we confirm their quality management systems and respond to issues. However, defects still occur in our manufacturing process, we launched a Supplier Quality Improvement Program (SQIP) to investigate and analyze the root cause of quality issues . In addition, under this program, for certain suppliers with high defect rates, we delve deep into defects that have already occurred to prevent reoccurrence and consider their repercussions, and focus on preventing other similar defects. The goal is to reduce the defect rate by 50% through ongoing efforts with suppliers and contribute to the further improvement of the relationships of trust with suppliers.

Responsible Sourcing of Minerals

The Group takes a sincere approach, as part of our corporate social responsibility, to the sourcing of minerals mined or extracted using illicit methods associated with human rights abuses or labor issues. We maintain a policy of eliminating the use of raw materials or components containing such conflict minerals.

In accordance with this policy, we conduct surveys on the responsible sourcing of minerals in accordance with the OECD*¹ Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas. In fiscal year 2025, we conducted our 11th annual survey, adding cobalt to the 3TG*² target minerals.

Through surveys using CMRT³ and EMRT⁴ to confirm the country of origin and smelters, we identified 298 smelters conforming to RMAP*⁵ standards, which is one basis for determining conflict-free sourcing. In addition, no sourced items were found to contain 3TG or cobalt mined or extracted by illicit methods.

If any significant concerns are identified, we will work closely with suppliers to take prompt corrective action. We share survey results with suppliers, request switching over to RMAP⁵-certified smelters, and continue to conduct due diligence activities to improve survey accuracy.

OECD: Organisation for Economic Co-operation and Development

3TG: Tantalum, tin, tungsten and gold

CMRT: Conflict Minerals Reporting Template. Survey format for reporting conflict materials, provided by the Responsible Minerals Initiative (RMI), which has established international guidelines on conflict minerals.

EMRT: Extended Minerals Reporting Template. A survey format provided by RMI for reporting on extended minerals such as cobalt, similar to CMRT.

RMAP: Responsible Minerals Assurance Process.A program promoted and led by the RMI for auditing smelters/refiners to validate that they do not use conflict minerals.

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|

| Number of identified RMAP conformant smelters

|

236 | 243 | 234 | 238 | 298* |

| Rate of identification | 100% | 100% | 100% | 100% | 99%* |

* From the fiscal year 2025 survey, cobalt has been added to the target minerals alongside 3TG (tantalum, tin, tungsten, gold).

Procurement BCP

As part of our business continuity plans (BCPs), we collaborate with suppliers on ongoing disaster preparation. To properly grasp our supply chain, which is becoming more complex, we are using IT systems for the visualization of our supply chain. At the same time, we maintain a database of suppliers’ production sites so that if a crisis arises, we can promptly identify impacted suppliers and quickly collaborate in recovery efforts. In fiscal year 2025, we analyzed the impact of earthquakes and tsunamis on our supply chain in anticipation of a Nankai Trough earthquake, and we request our suppliers to promote disaster prevention and mitigation measures against the Nankai Trough earthquake.

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|

| Percentage of suppliers for which supply chain BCP assessments were implemented | At least 85% | At least 85% | At least 85% | At least 85% | At least 85% |

| Rate of improvement after supply chain BCP assessment | 20.3 | 24.4 | 22.2 | 20.4 | 19.3 |

Environmental Initiatives

With the cooperation of our suppliers, we are promoting green procurement, prioritizing the purchase of environmentally friendly parts, products and materials. We also conduct surveys on product environmental laws and regulations for all parts and products purchased from suppliers, and we do not use parts or products containing chemical substances expected to be regulated in various countries. Rather, we switch to alternative products instead.

We also strive to establish and strengthen our environmental supply chain management through E-COMPASS initiatives. At the annual TEL E-COMPASS Day, we report on our E-COMPASS activities, provide the latest environmental information, and share information about activity policies. At the same time, we promote environmental initiatives across the entire supply chain together with our suppliers. We also grant the “Environmental Partners” to suppliers that especially cooperate in and contribute to our environmental efforts through E-COMPASS activities and certify them as "Green Partners."

On March 18, 2025, we held TEL E-COMPASS Day 2025, our fourth environmental activity briefing session for suppliers. The event was held in a hybrid format, with 745 supplier representatives participating both in-person and online. Focusing on product environmental laws and regulations as the main theme, we reported on our Group’s E-COMPASS activities, provided the latest and most accurate information on product environmental laws and regulations, and explained our activity policies. We also recognized four suppliers selected as Environmental Partners for fiscal year 2025. The four awarded suppliers participated in a panel discussion to share their initiatives. At the venue, we deepened communication with many suppliers, including 68 companies certified as Green Partners.

Building of Partnerships

For daily communication and as opportunities for strengthening relationships with our suppliers, each of our manufacturing sites in Japan holds production update briefings twice each year. We also hold TEL Partners’ Day annually. Through these events, we communicate and share information about our management policy, market trends, business policies, and sustainability initiatives with our suppliers. We also recognize suppliers as Excellent Partners who have achieved high evaluations in quality improvement, on-time delivery, cost reduction activities, and BCP assessments or TSSA.

In environmental activities as well, we award Environmental Partner recognition to suppliers with outstanding initiatives, expressing our appreciation for their cooperation and requesting continued understanding and collaboration in building a sound and sustainable supply chain. Beginning in fiscal year 2025, we launched the TEL Supplier Summit as a venue for building partnerships focused on core technologies, working with suppliers to develop technologies and further strengthen the supply chain. Overseas Group companies are also creating opportunities to share market trends and sustainability initiatives with major suppliers to build strong partnerships.

Source : Tokyo Electron

Education

Our group conducts web-based sustainability training for all employees, including buyers at manufacturing sites. We also hold study sessions for buyers on the requirements of RBA audit standards.

In fiscal year 2025, we distributed to our suppliers a booklet titled “Sustainability Introduction,” which summarizes our Group’s sustainability initiatives and compliance with laws and regulations. In addition, for suppliers cooperating with TSSA, we held an online briefing session to explain our RBA initiative plans and content and shared specific implementation methods and good practices as a means to help promote our suppliers’ own RBA initiatives.

Example initiatives (Global)

Since fiscal year 2023, Tokyo Electron Taiwan has been organizing TEL Taiwan Partners’ Day to build partnerships and strengthen supply chain management in Taiwan. Besides sharing the Group’s management policies and trends in the semiconductor industry, this event expresses appreciation for daily business activities and asks for cooperation in various future initiatives in hope of developing the industry and contributing toward society and the environment.

In addition, Tokyo Electron Korea has organized TEK Friends Day since fiscal year 2024 to share information about the state of the Group’s business activities, initiatives for net zero and sustainability, and other such information to strengthen communication and collaboration with suppliers.

Partnerships with Suppliers

In September 2022 at our headquarters, and in February 2023 at Tokyo Electron Technology Solutions, Tokyo Electron Kyushu, and Tokyo Electron Miyagi, we announced our “Declaration of Partnership Building” in support of the objectives of the “Council on Promoting Partnership Building for Cultivating the Future,” promoted by the Cabinet Office, the Ministry of Economy, Trade and Industry (METI), the Small and Medium Enterprise Agency (SMEA), and others. We will continue striving to enhance value across the entire supply chain and build strong partnerships with our suppliers.

Our approach to RBA

Membership in the RBA

In June 2015, we joined the RBA*, a world’s largest industry coalition dedicated to responsible business conduct in global supply chains. RBA has stipulated the RBA Code of Conduct to promote improvements in labor, health and safety, the environment, and ethics through the supply chain. We adhere to RBA Code of Conduct and working to build a sound and sustainable supply chain in collaboration with other RBA member companies in Japan.

Whistleblowing System for Suppliers

The Tokyo Electron Group has a supplier hotline for whistleblowing with the aim of early detection and the prevention of compliance issues.