Cleaning ANTARES™ Series

Production proven yield enhancing defect removal using a unique cryogenic inert gas technology

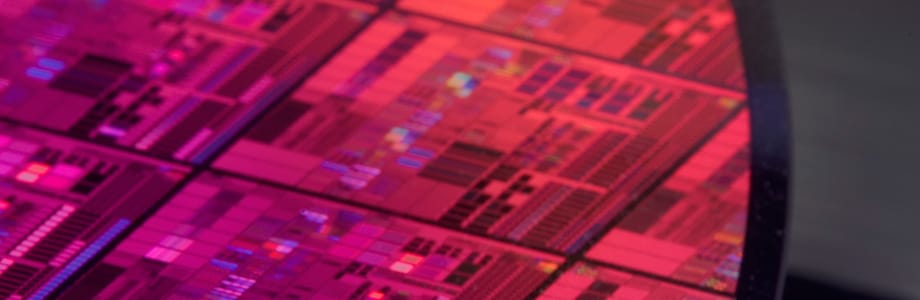

ANTARES™ is a series of a fully automated, single-wafer, CryoKinetic systems used for processing 300mm wafers. Each system uses cryogenic aerosol technology to safely remove nanoscale particles from device surfaces. Unlike conventional wet technologies, this all-dry process reduces defects without damaging the wafer surface, even on metal and low-k films. ANTARES™ series enables proven yield enhancing defect removal with no corrosion of metals, no watermarks on hydrophobic surfaces, and no wafer charging. The process is suitable for all materials.

ANTARES™ is a fully automated, single-wafer cleaning system that uses unique cryogenic aerosol technology to remove particulate contaminants and improve yield. The cryokinetic method is all dry and uses only inert gases, making it safe for processing even the most sensitive film types without surface reactions, roughening, or etching. ANTARES™ has been proven effective for yield enhancing defect removal across a wide variety of applications in the back-end and front-end.

Product comparison

|

|

| Wafer size (mm) |

300 |

| Availability | New |

| Wafer per batch | Single wafer |

| Throughput lilmit (hardware) | Application dependent |

| Spray method | Cryogenic aerosol |

| Chemical dispense | Chemical and water free aerosol |

ANTARES is a registered trademarks or trademarks of TEL Manufacturing and Engineering of America, Inc. in US and/or other countries.