Solutions that Create Value for Customers

Development of Global Operations

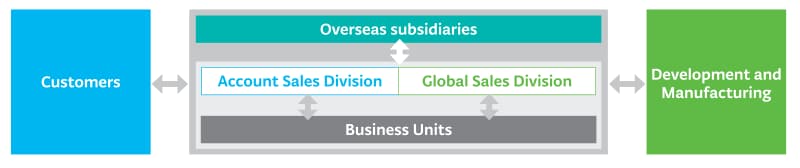

We established the Account Sales Division and the Global Sales Division, and strive to swiftly offer the technology, services and solutions sought by our customers to be the sole strategic partner for our customers. In the Account Sales Division, the needs for next-generation leading-edge technologies in memory, logic devices, foundry and other fields are shared by major semiconductor manufacturers, who are our traditional customers, and the information from this is used for the R&D of new technologies. The Global Sales Division responds to the needs of domestic and overseas customers that handle products for the rapidly growing Chinese market and the industrial IoT market.

These two divisions work closely with the Frontend and Backend Process Business Divisions' business units, development and manufacturing divisions, service divisions and overseas subsidiaries to conduct comprehensive sales activities. They strive to communicate with everyone from customer senior management to worksite engineers, to further strengthen our responsiveness to our customers and to develop global operations as ONE TEL.

Proposing Customer Solutions Leveraging a Wide Range of Product Lineup

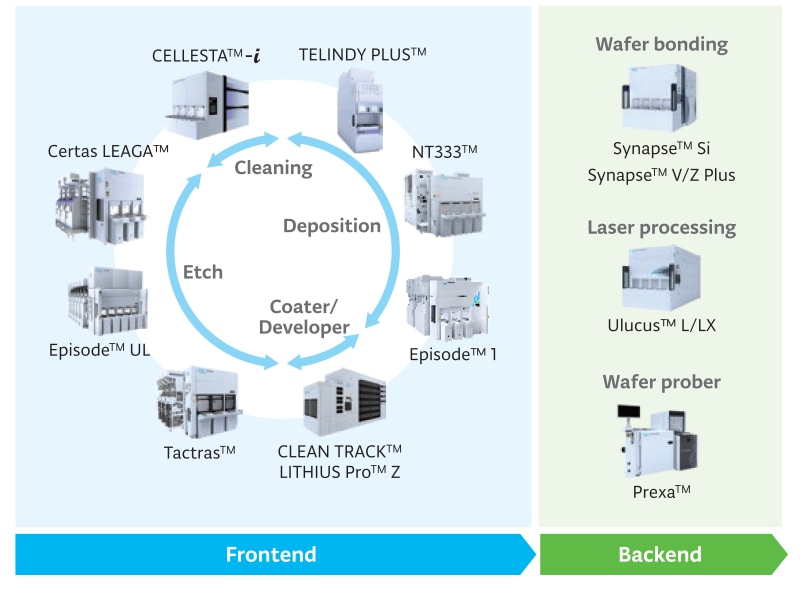

We are expanding the wide range of our product lineup, including equipment for the four key processes of deposition, coater/developer, etch and cleaning in the frontend process, as well as equipment for testing and bonding/debonding processes in the backend process. By leveraging this product lineup in our proposal activities, we will solve customers’ issues and contribute to the manufacturing of highly competitive semiconductors.

In the frontend process, we are undertaking the development of equipment with innovative and extreme processing performance, centered on (1) deposition systems that can handle new materials and structure while utilizing batch, semi-batch and single-wafer characteristics and allow optimal film thickness and film quality control, (2) coater/developers for leading-edge EUV lithography, (3) etch systems that achieve precision processing of fine structure and processing of deep holes and trenches with high selectivity, and (4) cleaning systems that remove particles and residues—which are causes of lower yields—without causing the collapse of fine patterns. Possessing equipment with four key processes allows us to propose solutions for issues faced by customers from a variety of approaches, including process integration based on an understanding of upstream and downstream processes.

In the backend process, we also possess wafer probers used in wafer testing and bonding/debonding systems that realizes 3D packaging. In the future, there will be a demand for further improvements in the performance of semiconductors as well as scaling technology using cutting-edge nodes to improve the performance in generative AI services and expand the application range. To achieve this higher performance, the introduction of advanced packaging technology called Chiplet is accelerating, which combines individualized semiconductors. To meet these demands, we will proactively provide solutions for bonding processes necessary for both next-generation scaling technology and packaging technology, and introduce KGD* testing equipment, essential for Chiplet.

KGD: Known Good Die. Semiconductor chips with guaranteed quality, including reliability