Customer Satisfaction

Initiatives for Improvement of Customer Satisfaction

We are working to build solid relationships of mutual trust with customers by enhancing customer satisfaction, which we have valued highly since our founding. We co-create future technology roadmaps with the semiconductor manufacturers that are our customers to promote the concurrent evaluation of technologies four generations into the future and beyond and accelerate the technological development of Shift Left. This allows us to offer highly

competitive products that help improve customers’ productivity by improving the yield rate of devices and maximizing equipment utilization rate. Furthermore, at customer sites around the world, we are continuously implementing customer-oriented initiatives such as assigning our company engineers to quickly install equipment to operate at maximum performance, proposing solutions to any specific technical issue and providing feedback on next-generation equipment.

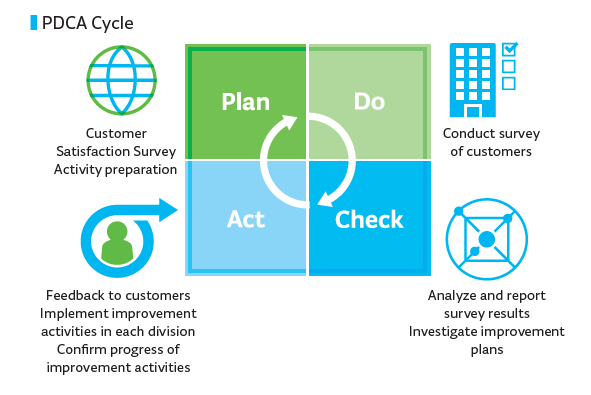

In addition to these activities, we conduct our own Customer Satisfaction Survey* every year. In the fiscal year 2025 survey, we received responses from approximately 1,800 customers (response rate: 82.4%). We analyzed this information and used it in our PDCA cycle to make improvements at the actual operation level.

Our activities were highly evaluated and we received best awards consecutively from many of our customers in fiscal year 2025. We will continue to provide the Best Products with innovative technology and Best Technical Service with high added value and strive to further improve customer satisfaction.

Customer Satisfaction Survey

We conduct our own customer satisfaction survey and use the feedback we receive from our customers to improve our services. This survey, which started in certain divisions in fiscal year 2004, expanded to cover all semiconductor production equipment divisions in fiscal year 2014, and the display production equipment division and overseas subsidiaries in fiscal year 2016. This survey, known as the Customer Satisfaction Survey Program (CSSP), is now conducted company-wide.

The CSSP is conducted annually at the same time each year. We analyze the collected data by unit (product), account (customer) and function (software, development, etc.), and shares the results with related departments such as sales, manufacturing, and service, enabling practical improvements at the operational level. Additionally, we continuously refine all aspects of the CSSP, including survey questions, analysis methods, and overall program management.

In the survey for fiscal year 2025, approximately 1,800 customers responded (a response rate of 82.4%), with an average score of 3 points or higher ("very satisfied" or "satisfied") for all survey items*, allowing us to achieve our annual sustainability goals for the fourth year in a row. On the other hand, we are promoting Shift Left, which is an early-stage improvement initiative, such as promptly responding to customers who gave a score of 1 "Very Dissatisfied."

We will continue to work as company-wide to engage in CSSP activities so that we can continue to achieve our annual sustainability goals in the future.

For each question, average score is calculated for all customers who responded

Improvement Activity Examples

Among all 30 items, while the two items related to software achieved a target score of three points or higher ("Very Satisfied" or "Satisfied"), their scores continue to lag behind those of other items. Therefore, the entire Group as a whole is implementing the following improvement measures.

- Improving software development speed through enhancements to development tools and common platforms

- Strengthening relationships between customers and software engineers by actively hearing customer requests and sharing development progress

- Strengthening on-site responsiveness by providing software-related education to frontline personnel (including overseas field engineers and data scientists)

By deploying the PDCA cycle through these improvement measures, we strive to further enhance customer satisfaction with our software division.