Field Solutions

Strengthen Customer Responsiveness of Field Engineers

With an outlook to further expand the scale of our business, it is extremely important to increase field engineers, develop people that can promptly play an active role as well as effectively improve the skills of existing field engineers.

Our company establishes a Group-wide common skills management system that meets the standards of Semiconductor Equipment and Materials International (SEMI) and plans to continuously upgrade skills based on the detailed goals established every year. The system helps us to improve the quality of the services we provide to customers, by enabling the optimized deployment of human resources that utilize information about engineers’ skills which have been managed in this manner.

Furthermore, we are expanding our program to reassign engineers who had undergone training at manufacturing sites in Japan for a fixed period to the field after their return to their companies, as part of our education for expert engineers for overseas subsidiaries. In this program, engineers strive not only to deepen their knowledge of equipment technology but also to further improve communication with development and manufacturing divisions and business units. They strive to provide high quality services to customers through support in solving technological issues and problems in response to demands from engineers stationed at their respective overseas subsidiaries, in addition to receiving training during the program. This enables engineers to consistently understand customers’ situations appropriately and in a timely manner and their further contributions upon return from Japan as site leaders is anticipated.

To make this expert engineer training program easier to take, we develop and operate short-term programs that subdivide the content and focus on specific skills and knowledge. By taking various programs based on needs, engineers can share the skills and knowledge they acquired after they return from Japan with each subsidiary, and we strive to raise the overall skill level of subsidiaries in this manner.

Going forward, we will further expand the on-site leaders’ skill up program to quickly resolve our customers' issues.

Support Services that Extend the Life Cycle of Equipment

As part of our efforts to have our customers use our equipment over a long period of time, we provide LEAP*, a support service that extends the life cycle of our equipment. Support for semiconductor production equipment typically ends seven to eight years after discontinuation of equipment due to the discontinuation of parts or the difficulty in maintaining safety and quality. For this reason, equipment for which support has ended is discarded and replaced with succeeding equipment. We now provide support service that makes the extension of the life cycle of equipment whose production was discontinued over 15 years ago possible by redesigning discontinued parts and restructuring and strengthening our support system including repairs.

We support customers who have difficulty with replacement with newer equipment due to restrictions on change management of equipment specifications or operations, or who hope to continue using their equipment. Through this support, while implementing initiatives that reduce equipment disposal and environmental impact, we contribute to the continuous operation of customers' equipment over a long period of time.

LEAP: Lifecycle Extension and Availability Program

Provision of Best Technical Service with High Added Value

In recent years, factors demanded by customers include high level support technology to deal with manufacturing processes that realize scaling and multi-layering of semiconductor devices, further improvements in productivity and reductions in environmental impact. To provide Best Technical Service with high added value that respond to these needs, in addition to developing field engineers, we promote the development and introduction of systems that incorporate digital and information and communication technology that support engineers’ field work as well as tools to raise work efficiency.

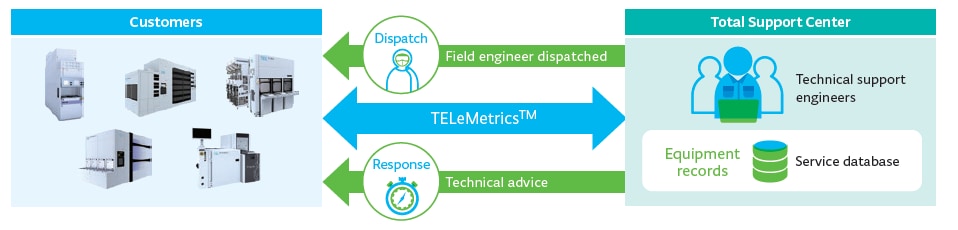

By accumulating large amounts of operation history, such as equipment support in everyday activities in Service CRM, which centrally manages globally, as well as creating equipment records and building troubleshooting search tools as knowledge management activities, onsite field engineers use these tools to provide prompt and high-quality services to our customers. We are also developing a system that centrally manages operation procedures used by field engineers onsite and that improves the efficiency of procedure creation, quality, and searchability of operation procedures, and are rolling them out globally. In addition, we strive to resolve our customers’ various issues through the use of remote support tools that connect the server installed in the customer’s clean room to our system, which makes remote operational support possible.

Our company provides several contractual services for the stable operation of equipment, such as services in which our field engineers are stationed at customers’ manufacturing sites to maintain their equipment, as well as a comprehensive contractual service (TEL Service Advantage Premium) in which we offer pay-as-you-go or flat-rate maintenance services, supply maintenance/consumable parts and repairs in an integrated manner. Furthermore, to shorten issue resolution time and stabilize process performance, we aggregate and analyze data output from equipment, predict the timing of failure of major parts and suggest replacements in advance so that we can help improve our customers’ equipment utilization rates.

Engineer’s Skill Up

In fiscal year 2019, we established our training operations center to enhance the training structure and promote globalization of field engineers. The center establishes a company-wide common skills management system that meets the standards of SEMATECH (a U.S. consortium for the joint development of semiconductors). The system helps us to deploy the most suitable human resources to provide customers with service based on an objective measurement of the skills of our engineers.

In fiscal year 2021, we began providing education for expert engineers to improve the skills of engineers at our overseas subsidiaries. The education includes training programs that enable technical support engineers from overseas to learn not only technical support but also acquire advanced skills related to development in a practical manner at our manufacturing sites in Japan. Furthermore, we also conduct training for field engineers of our Global Data Engineering Team, established in fiscal year 2021, to develop data analysts specializing in digital transformation (DX)*.

In fiscal year 2022, field engineers who have acquired DX skills developed a program for the continuous improvement of business operations and are rolling it out globally. By linking this program to the field information database, it became possible to automatically update, analyze and visualize field information.

Digital transformation:refer to Higher Productivity through Digital Transformation (DX)