Quality

TEL Quality Global No.1

Knowing our customers' real needs enables us to attain world-leading product quality.

Approach to Quality

Tokyo Electron defines it's approach to quality in the following way: “The Tokyo Electron Group seeks to provide the highest-quality products and services. This pursuit of quality begins at development and continues through all manufacturing, installation, maintenance, sales and support processes. Our employees must work to deliver quality products, quality services and innovative solutions that enable customer success.” We strive to implement this policy.

- Quality Focus

- Focusing on quality to satisfy customers, meet production schedules, and reduce required maintenance even with temporary cost increases.

- Quality Design and Assurance

- Building quality into products and assure in-process quality control, from the design and development phase throughout every process.

- Quality and Trust

- When a quality-related problem occurs, working as a team to perform thorough root cause analysis and resolve problems as quickly as possible.

- Continual Improvement

- Ensuring customer satisfaction and trust by establishing quality goals and performance indicators and by implementing continual improvement using the PDCA cycle.

- Stakeholder Communication

- Listening to stakeholder expectations, providing timely product quality information, and making adjustments as needed.

Since the Quality Policy has direct bearing on each employee's actions, it applies not only to the manufacturing sites but also to headquarters and all domestic and overseas sites. Posters in English, Chinese (simplified characters), and Korean, as well as Japanese, have been created to disseminate this policy, and are distributed and displayed at each company and all sites.

We have established rules based on our companywide Quality Policy, which are systematically organized as the TEL Manual (TM) and the TEL Guidelines (TG) for each major business category, such as development, design, manufacturing and service. These rules are shared and used across the entire Group, including manufacturing sites, and suppliers.

As compliance with common rules become the basics for quality assurance of products and services, our Corporate Quality Division regularly confirms the level of understanding of, and compliance with, the operational rules in our manufacturing and service sites. Additionally, we are working with our suppliers on strengthening our quality improvement system by having each manufacturing site implement regular quality inspections for our suppliers.

Furthermore, each manufacturing site builds a quality management system based on the TM and the TG and has attained ISO 9001:2015, the international standard for quality management systems. Furthermore, we are striving for continuous improvement in our quality management system by efficiently operating the PDCA cycle through repeated internal audits and third-party organization audits. The Quality Assurance Division in each Group company sets quality goals every year based on the results of the previous year, and regularly reviews the progress of achievement of those goals. Specifically, we monitor the number of non-conforming*¹ products delivered from suppliers and confirm the monthly progress of defects by making them KPIs to evaluate the status of reductions based on the number of defected parts delivered in the previous fiscal year.

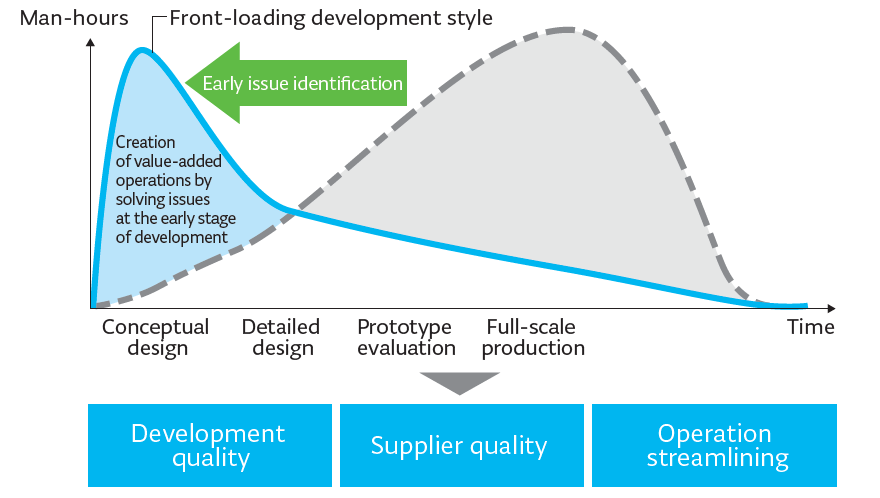

In addition, through self-process assurance*², we conduct strict quality risk management and development/design inspections and thoroughly pre-validate customer operations through simulations. Through these initiatives, we work to improve the accuracy of each process and reduce the reworking costs*³, and we promote “Shift Left” (front-loading), which enables employees to focus on high-value-added work in the upstream processes. Specifically, shifting to a design process that centralizes and shares risks from a design process that identifies risks according to each development and design project, leads to the prevention of failing to identify risks. We are also improving our ability to respond to innovative development by identifying newly anticipated risks based on examples of past issues and establishing frameworks in which those risks are reflected in business processes.

*¹ Non-conformance: Quality issues such as defects or flaws occurring within in-house manufacturing processes

*² Self-process assurance: Comprehensive measures that prevent non-conformance in each process and prevent such products from passing through to subsequent processes

*³ Reworking costs: Costs incurred by going up the chain of processes and reworking when there is non-conformance

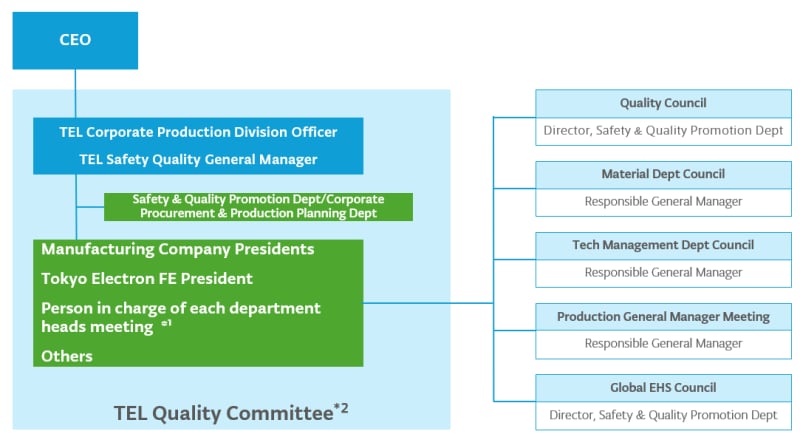

To provide consistent, high-quality products, we have built and are implementing quality assurance systems under the leadership of the CEO. All manufacturing companies in the entire Group have attained certification in the latest quality management system, ISO 9001. In addition, we conduct regular internal audits as well as neutral and fair audits by third parties for each manufacturing company of the Group to contribute toward maintaining and improving our quality management systems.

*¹ Department Heads Meeting: Held quarterly to resolve shared issues in business processes and to facilitate horizontal deployment within the Group. It is composed of department heads from each BU and business location.

*² TEL Quality Committee: The presidents’ meeting of manufacturing companies and reports/decisions made at the quarterly board meetings of affiliated companies are treated as equivalent to the TEL Quality Committee.

ISO 9001 Certified Plants and Offices

| Company Name | Plant/Office Name | Certification Number | Certification Date | Update Date |

|---|---|---|---|---|

| Tokyo Electron Technology Solutions | Fujii Office/Hosaka Office | 00225-1994-AQ-KOB-RvA | Sep.1994 | Oct. 2022 |

| Tohoku Office | Dec. 1994 | Oct. 2022 | ||

| Tokyo Electron Kyushu | Koshi Office | 5569-1997-AQ-KOB-RvA | Mar.1997 | Feb. 2023 |

| TEL Magnetic Solutions | - | IE09/66498 | Nov.2009 | Nov. 2024 |

| Tokyo Electron Miyagi | Taiwa Office | 02609-2012-AQ-KOB-RvA | Sep.2012 | Sep. 2024 |

| Tokyo Electron Korea | Balan Plant | QSC1680 | Sep.2011 | Aug. 2023 |

| TEL Manufacturing and Engineering of America | Chaska Office | FM586277 | Mar.2013 | Mar. 2025 |

| Tokyo Electron (Kunshan) | - | 260147-2018-AQ-RGC-RvA | May 2018 | May 2024 |

Process Improvement Activities

The production sites of our customers require limited variations in quality between equipment, accurate process repeatability and high productivity. To provide products that match such customer needs, we focus on process improvement activities (PCS*) using a statistical method.

We create control diagrams for the information of various types of critical components (components directly in contact with wafers and components that directly affect the process of systems, such as components that transfer mechanical, thermal, electrical or electromagnetic energy to wafers) and analyze variations to quickly detect and respond to changes in manufacturing processes. By undertaking such PCS activities together with suppliers handling specific critical components, we work on the suppression of component quality variability and maintenance/improvement of manufacturing processes that produce quality products to help provide products surpassing customer expectations.

In addition, manufacturing processes handling new critical components need constant review and improvement. Our products comprise several tens of thousands of components, and the task to select specific components from these and carry out regular aggregation and analysis require many man-hours.

To optimize and streamline this task, we reexamine our operational flow, including the adoption of automation, and improve our systems by collecting information from customers, holding discussions among our manufacturing sites in Japan and interviewing our suppliers. By continuously carrying out these activities that are based on the concept of Shift Left, we are striving to improve our productivity further.

PCS: Process Control System

Example Initiative

At Tokyo Electron Technology Solutions (Tohoku), design of experiments* based on statistics is used to establish quality metrics for critical components and the level of quality activities is being improved together with suppliers.

The best quality metrics established using the designs of experiments are set as the targets. Conditions that give rise to variations in inspection, adjustment and other values in the manufacturing processes of critical components are strictly managed using PCS activities to seek accuracy and stability in the manufacturing processes.

In the future, we will promote the automation of processing—from collection to assessment—of suppliers’ data regarding quality and detect the state of quality in real time to further improve the manufacturing processes of critical components.

Design of experiments: A branch of applied statistics that aims to design efficient experimental methods and properly analyze the results

Ensuring Self-process Assurance Systems and Promoting Shift Left

In order to improve the quality of products, it is important to prevent non-conformance from occurring in upstream processes and to ensure thorough quality control in each process so that nonconforming products— if they occur—are not allowed to flow into later processes. From this perspective, we promote activities focused on self-process assurance systems. In particular, we aim to further improve quality by implementing thorough risk detection and mitigation measures (FMEA*1) from the initial stages of product design, as well as carrying out thorough inspections in each process and conducting verification using simulation.

These activities for in-process quality control make it possible to create high-value-added technologies and products in the upstream processes by improving the precision of each process and reducing reworking costs*2, and at the same time, lead to the promotion of the Shift Left*3 concept.

We are also promoting Product Lifecycle Management (PLM) by using in-process quality control to comprehensively manage and analyze all processes from product planning, development, design and production through to service in an effort to facilitate the earlier release of products, enhance operational efficiency, improve quality and reduce costs.

FMEA: Failure Mode and Effects Analysis.Refer to Approach to Quality

Reworking costs: Costs incurred by going up the chain of processes and reworking when there is non-conformance

Shift Left: Refer

Shift Left (Front-loading) Initiatives

Measures to Prevent Quality Problems from Occurring and Recurring

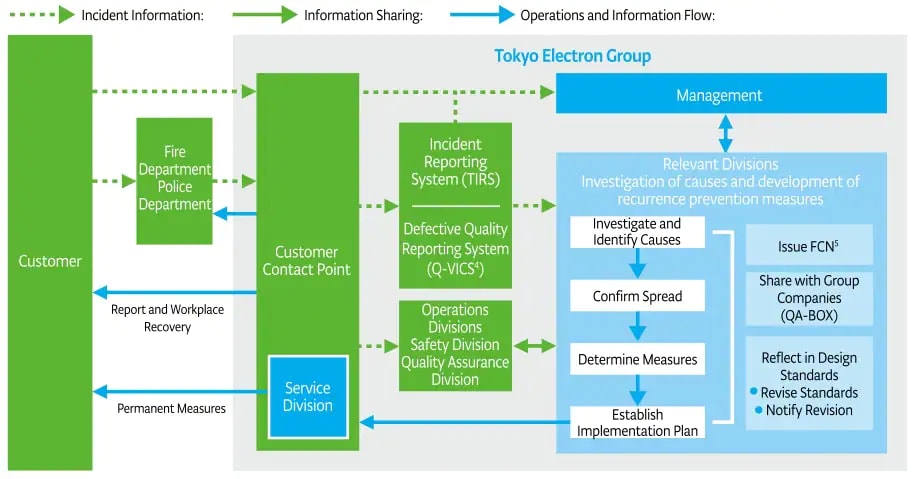

To comply with ISO and EN*1 safety standards and achieve higher safety levels, we have established its own design rules for each product. At the same time, we have developed systems for manufacturing products, which include safety considerations. We also have other systems in place for responding to issues such as equipment design and production non-conformance and any occupational incidents.

In the event of an incident, we use our TIRS*2 incident reporting system to distribute information to safety and quality personnel in each division and officers and management, including senior management. An incident investigation is also conducted immediately to identify the cause and plan preventive measures.

When a quality defect*³ occurs, a field engineer receives a notification from the customer and submits it to the quality issue management system Q-VICS*⁴. Relevant departments at each site analyze the defect, promptly implement countermeasures addressing the root cause, and work to prevent recurrence of similar issues and occurrence of new issues.

If an FCN*⁵ occurs, our internal regulations define that countermeasures should be completed within one year. Based on these regulations, regular meetings are held between each manufacturing site and the field engineer department to carry out countermeasures according to plan. In addition, the corporate quality division checks monthly the number of pending countermeasures and the number of affected units for all products and works to promote countermeasures in cooperation with relevant departments at each site.

We use a proprietary system called QA-BOX*⁶ to share information on equipment quality and any major non-conformance across all quality departments in accordance with our operating rules. Measures obtained from the results of an incident investigation are promptly applied, not only to the problem equipment but also to relevant equipment operated by other customers. At the same time, after finding the root cause, revisions are also made to the current design standards and processes to perpetually prevent the occurrence of major non-conformances.

For departments that become subjects of incident investigations, we validate repercussions to other equipment and commonalities and share the issues and countermeasures at regularly scheduled QA-BOX meetings together with the heads of quality assurance divisions. This allows us to examine various approaches to prevent similar non-conformances. The common policies determined at the regular meetings are quickly deployed across the entire Group and reflected in the respective equipment. This helps to reduce nonconformances caused by equipment.

Example Initiative

At Tokyo Electron Technology Solutions (Tohoku), multiple systems were conventionally used for responding to issues, which required significant time for investigation and analysis. To address this, an application was developed that allows cross-operational use of multiple systems through a single interface, improving system operability and shortening response time to further enhance the efficiency of issue resolution.

Accident and Issue Handling Flow

EN: European Norm. Uniform standard for the European Union complimenting parts of technical standards not stated in European Commission directives (“New Approach” directives)

TIRS: TEL Incident Report System

(Quality) issue: Quality problems such as defects or flaws discovered at customer sites

Q-VICS: Quality Valuable Information Chain System

FCN: Field change notice. Refers to the general recall notice

QA-BOX: Tool for the sharing and horizontal deployment of important quality-related information within our Group companies

Initiatives with Suppliers

Continuously improving quality based on strong partnerships with suppliers is essential for providing high-quality products quickly to the market. Since fiscal year 2001, we have conducted our unique Supplier Total Quality Assessments (STQA) in an effort to ensure our suppliers properly understand the level of quality expected from them.

Before starting a new business with suppliers, we conduct an STQA via self-assessment to evaluate their product quality, costs and information security. The assessment also includes their corporate social responsibility initiatives, including human rights, ethics, safety, and the environment. If a risk is identified in this assessment, we visit the supplier and confirm the area of non-conformance on-site.

Once our approaches to quality and other important related issues have been shared with the supplier, we request that they plan and implement improvement measures and provide continuous support until all of them have been completed. In addition, we also conduct audits once every three years for suppliers who handle important components and for suppliers where quality issues have been found.

We also hold regular meetings with the leaders of various manufacturing sites in Japan who use STQA to share supplier-related information and discuss measures to resolve issues.

Example Initiatives 1

At Tokyo Electron Kyushu, to prevent similar non-conformances from recurring at other suppliers, in addition to regular quality management audits, audits focusing on technical responses have been conducted based on actual non-conformance cases. In fiscal year 2026, this initiative will be shared with other manufacturing sites, and similar audits will be carried out to improve the quality of the entire Group.

Example Initiatives 2

At Tokyo Electron Miyagi, only suppliers with a high number of part non-conformances were evaluated for non-conformance count and response capability. However, since 2023, this initiative has been expanded to all suppliers where part non-conformance has occurred. A quality report is issued, and quality evaluation levels are established to raise awareness of quality issues, thereby reducing parts non-conformance and fostering quality consciousness.

Quality Education

We are striving to enhance the awareness of every employee toward quality by conducting various education programs.

Basic quality education is provided for new employees, and continuous business improvement education is also implemented for all employees.

We also implement our own education program, called TEL 6-Step, for employees closely involved in quality control, such as developers, designers, quality managers, and service personnel, through which they acquire a problem-solving model to handle important issues. The program is a modified version of the eight discipline (8D) problem-solving method*¹, widely used in quality control, customized to replace our problem-solving process. The program cultivates the ability to resolve problems quickly and to take measures preventing recurrence, by thoroughly investigating the true nature of problems, and determining the technical factors and root causes. As of fiscal year 2025, approximately 8,800 employees (cumulative total) had attended this program. Moreover, so that employees can tackle quality improvement autonomously, we advocate QC certification*² and encourage them to acquire fundamental skills. The number of QC certified employees has increased yearly to approximately 3,400 (cumulative total) as of fiscal year 2025.

8D problem-solving method: A method for solving problems in quality improvement through eight disciplines or processes

QC certification: Quality management certification operated by the Japanese Standards Association and the Union of Japanese Scientists and Engineers. The total number of certified people nationwide exceeds 770,000 (as of March 2025)