Our approach to RBA

Membership in the RBA

Tokyo Electron Group is actively engaged in building a sound and sustainable supply chain, with particular focus on two material issues: “respect for human rights” and “supplier relationships.” While the importance of semiconductors in society continues to grow, challenges such as environmental issues, human rights, labor, health and safety, ethics, and compliance are also becoming increasingly significant. This requires companies to enhance their efforts accordingly. In this context, maintaining and continuously developing the integrity of the supply chain at a global level necessitates industry-wide collaboration to reduce risks and address challenges.

In June 2015, we joined the RBA*, a world’s largest industry coalition dedicated to responsible business conduct in global supply chains. RBA has stipulated the RBA Code of Conduct to promote improvements in labor, health and safety, the environment, and ethics through the supply chain. We adhere to RBA Code of Conduct and working to build a sound and sustainable supply chain in collaboration with other RBA member companies in Japan.

Promotion Framework

We have established a system to promote RBA activities under the supervision of an Executive Officer in charge of sustainability promotion. Under the oversight of this Executive Officer, the Corporate Sustainability Management department plays a central role, collaborating with related departments at headquarters—including the Procurement and Human Resources departments—as well as Sustainability Managers appointed within each Group companies. Together, we work to advance the RBA initiatives across the Group.

Initiatives Toward Compliance with the RBA Code of Conduct

We promote initiatives to ensure compliance with the RBA Code of Conduct throughout the entire supply chain, monitoring adherence through assessments and audits.

Implementation of Assessments

We conduct annual compliance assessments at our manufacturing sites in Japan and overseas using the RBA’s Self-Assessment Questionnaire (SAQ). The SAQ consists of questions related to human rights and labor, occupational health and safety, environment, ethics, and relevant management systems. It assesses risk levels as Low, Medium, or High based on the status of risk mitigation efforts. In fiscal year 2025, the SAQ was conducted at eight sites in Japan and overseas. Although no sites were rated as High Risk, we identified areas requiring improvement in compliance and are in the process of developing and implementing corrective measures.

In addition, since 2013, we have been implementing the "TEL Sustainability Supply Chain Assessment (TSSA)," which incorporates additional human rights questions beyond the requirements of the RBA audit standards. Each year, we request cooperation from our suppliers in the materials, staffing, logistics, and facility management sectors to participate in the survey. In fiscal year 2024, the survey was conducted with 704 suppliers, and in fiscal year 2025, we undertook corrective actions based on the survey results. For fiscal year 2026, we have revised the questionnaire to align with the latest version of the RBA Code of Conduct and added questions regarding human rights and inherent risks related to countries and business activities. The survey is being conducted with 714 suppliers.

Remediation Activities

Based on the SAQ results, our domestic sites have identified areas requiring improvement, such as reducing working hours, documenting policies and procedures, establishing management systems, and adding minerals subject to responsible mineral sourcing investigations, and are undertaking corrective actions in these areas. For our suppliers, we provide feedback to all suppliers who responded to the assessment, including overall results, year-over-year trends, average scores, and individual evaluations. We also ask suppliers to implement corrective actions for identified non-compliance issues. The items with the most frequent non-compliances include documenting policies and procedures, reducing working hours, conducting evacuation drills, and first aid measures.

Main Non-Conformance Item

| Labor | Working Hours: Management of weekly working hours |

| Labor | Wages and Benefits: Pay reduction (disciplinary pay cuts) |

| Health and Safety | Emergency Preparedness: Evacuation drills |

| Health and Safety | Work-related Injuries and Illnesses: First aid personnel |

| Management System | Documentation: Establishment of policies and procedures |

| Management System | Supplier Management Responsibility: Communication of the RBA Code of Conduct |

As part of enhanced monitoring measures in fiscal year 2025 in addition to the initiatives described above, we individually verified corrective plans and the implementation status with 55 of our suppliers, and supported remediation activities by sharing best practices. Moreover, regarding the issue of "worker-paid recruitment and employment related fees," which falls under the category of forced labor, we conducted detailed confirmation through engagement with 12 staffing suppliers whose responses raised human rights risk concerns. Through engagement, some suppliers where risks were identified, took corrective measures such as revising internal operations and documenting procedures to prevent recurrence, after gaining an understanding of the issues and the need for corrective action. Furthermore, regarding working hours—identified as a common challenge for both our company and our suppliers—we ensure compliance with legally mandated "working hours, holidays, and leave." We also have established and are promoting management standards aligned with the criteria set forth in the RBA Code of Conduct, advancing efforts to prevent excessive labor and reduce overtime work.

Some of the best practices from our suppliers

Labor

|

Safety

|

Supply chain management

|

As of the end of fiscal year 2025, of the 137 corrective items planned at 55 suppliers, we confirmed completion of 64 items. Because some corrective items require medium-term efforts to complete, we will continue to work with our suppliers and monitor progress in fiscal year 2026.

Briefing Sessions for Suppliers Regarding Assessments

We regularly conduct briefing sessions for suppliers in the materials, staffing, logistics, and facility management who cooperate with our assessments. In April 2025, approximately 780 representatives from our suppliers participated in the session, where we explained our Group’s supply chain initiatives and the assessment process, and requested their continued cooperation for future activities. Additionally, we reported on the results of the previous assessment and shared insights on supply chain risks with our suppliers.

Online briefing session

Undergoing RBA Audits

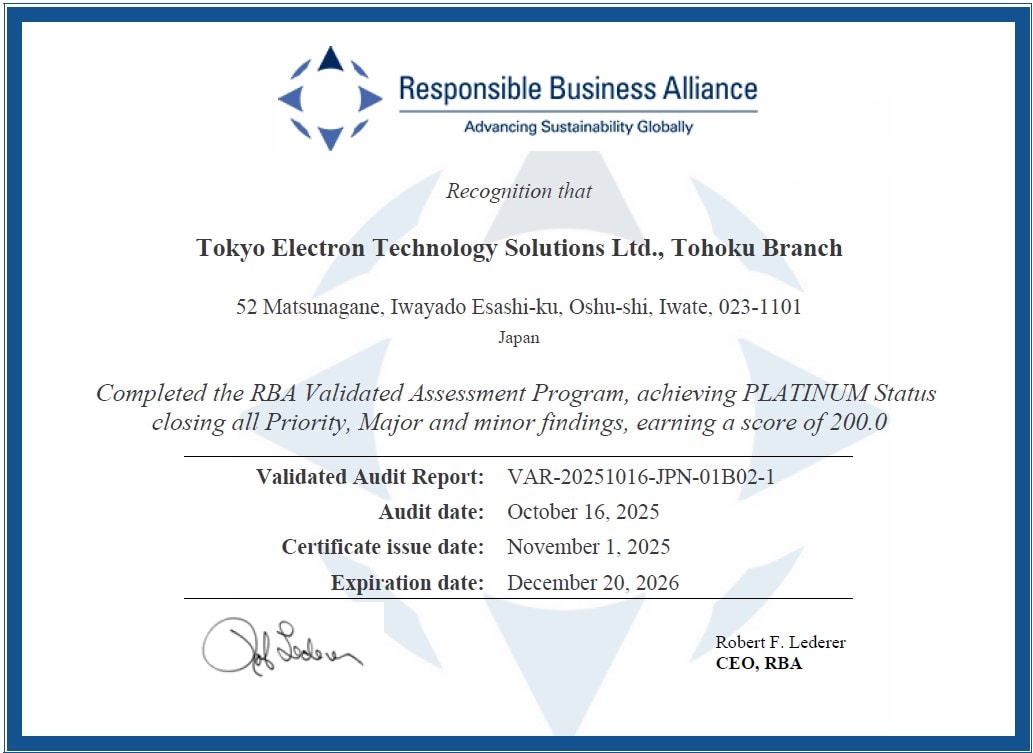

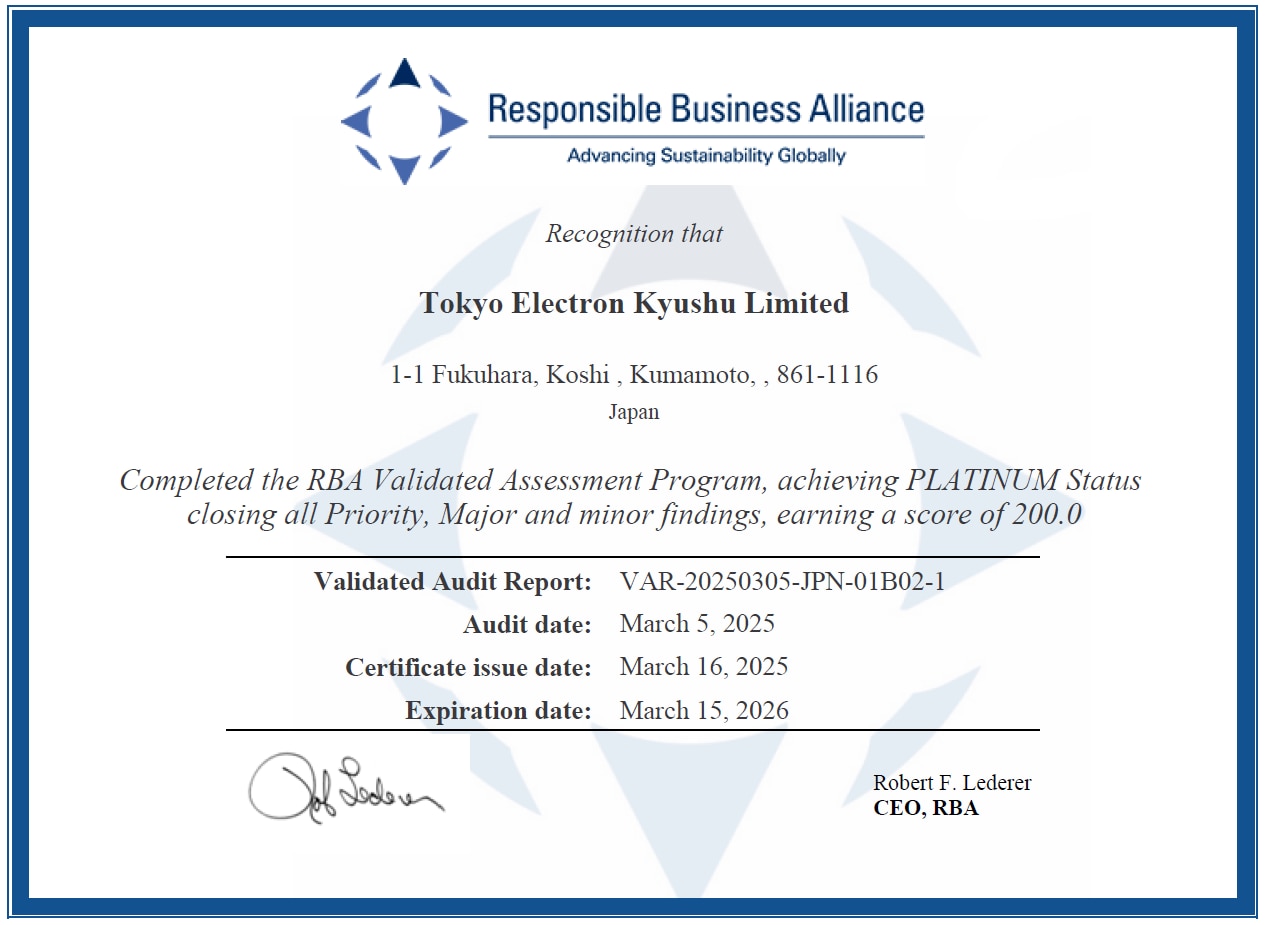

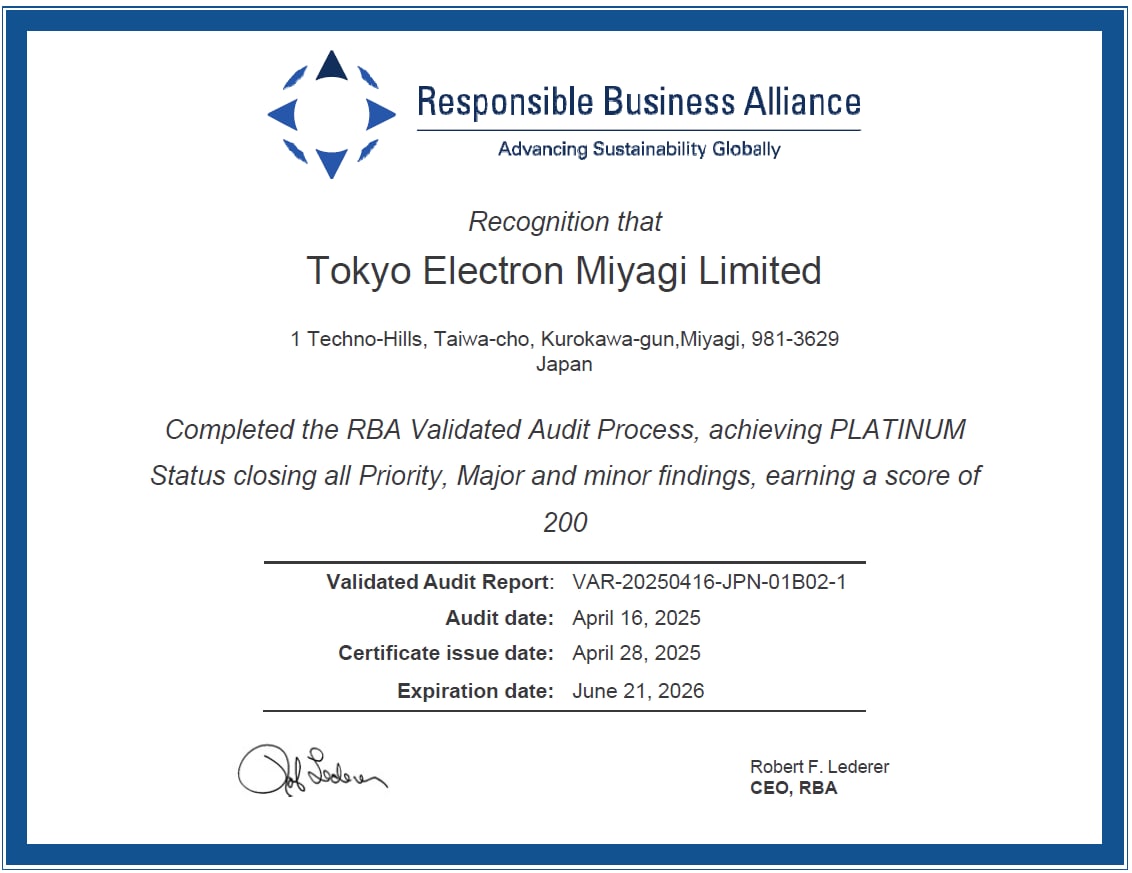

Since 2022, the Group has been proactively participating in the RBA’s third-party Validated Assessment Program (VAP). The VAP audit evaluates whether business activities comply with the RBA Code of Conduct, and based on the evaluation score (160 points or higher), sites are certified with a status within the RBA certification program. In 2025, four of our sites underwent closure audits and were recognized for proper management and operation across all categories, including Labor, Occupational Health and Safety, Environment, Ethics, and Management Systems. Both sites achieved the highest score of 200 points and were certified with Platinum Status.

Status of RBA VAP Certification

| Company Name | Plant/Office name | Acquisition Date | Score | Status | |

|---|---|---|---|---|---|

| Tokyo Electron Technology Solutions |

Head Office, Hosaka |

July 2023 |

200 | Platinum | |

| Aug. 2025 | 200 | Platinum | |||

| Tohoku | Nov. 2025 | 200 | Platinum | ||

| Tokyo Electron Kyushu | Head Office | Mar. 2025 | 200 | Platinum | |

| Tokyo Electron Miyagi | Head Office | Apr. 2025 | 200 | Platinum | |

Awareness and Education Activities

The Group conducts web-based training on the RBA Code of Conduct for all employees and includes it as part of the onboarding program for new employees in Japan every year. In the training, we explain the purpose and significance of initiatives in the areas of “Labor & Human Rights,” “Health and Safety,” “Environment,” and “Ethics,” provide detailed explanations of each item, and introduce our Group’s practices to encourage each individual to take action. Additionally, we hold study sessions on the requirements of the RBA audit standards for personnel involved in RBA VAP audits and buyers who support our suppliers' efforts.

For our suppliers, we regularly hold briefing sessions to deepen their understanding of the RBA Code of Conduct and to explain our Group’s plans and activities related to RBA initiatives.

Engagement with the RBA

Since joining the RBA, our company has supported its mission and vision and has been actively advancing RBA initiatives. We collaborate closely with the RBA through participation in various working groups and activities such as the Japan Outreach Meeting. The Japan Outreach Meeting held in April 2025 was attended by approximately 225 participants, including representatives from member companies in Japan and their supply chain partners. Our company presented in a session titled “Policy Initiatives as the Driver of Responsible Business Conduct,” engaging in discussions on the rapidly evolving regulatory landscape related to sustainability.