TEL Announces the Launch of Impressio™3300 PICP™, a Dry Etch System for Manufacturing G10.5 High-Definition Flat Panel Displays

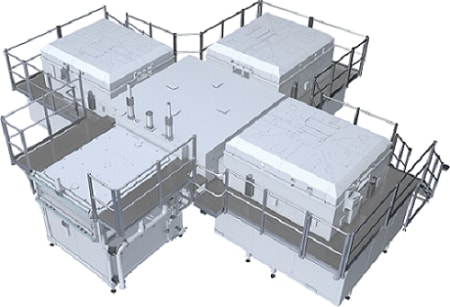

Tokyo Electron (TEL) announced today the launch of Impressio™3300 PICP™, a dry etch system with a high density plasma source that enables high resolution processing of G10.5 (2,940 mm x 3,370 mm) glass substrates.

The flat panel display (FPD) industry has been enhancing the resolution of large liquid crystal display (LCD) products, as represented by the commercial introduction of 8K TVs. The demand for high quality displays is also spurring the production of organic light-emitting diode (OLED) displays. Many of these advanced displays typically use oxide semiconductors to power their driver circuits. Since oxide semiconductor production processes require higher precision and efficiency compared with amorphous silicon processes, which have been the norm for large panels, dry etch systems for oxide semiconductors must offer faster etch rate, better within-substrate uniformity, and higher yield than conventional equipment.

The PICP etch module is equipped with a high density plasma source, which has been uniquely conceived and developed by TEL to address the advanced technology needs of oxide semiconductors and other new devices. Compared with its predecessor, ICP-duo, the PICP module is 20% more energy efficient in terms of plasma process, and offers significant improvement in productivity and process uniformity with lower running cost. The newly released Impressio3300 PICP is a unique dry etch system that introduces the PICP module to G10.5 panel processing, and can be used for producing high-definition LCDs and OLED displays.

“Coming with the PICP module that is production proven with small to medium-sized ultra-high-definition panels, the Impressio3300 PICP is ideal for manufacturing larger panels with high resolution and superior picture quality,” said Hiroshi Ishida, TEL Vice President & FPD Business Unit General Manager. “The system will deliver significant improvement in process uniformity of advanced processes, while also reducing power consumption to achieve better productivity so we remain responsive to our customers’ needs.”

TEL is committed to providing innovative technologies and effective solutions that satisfy market needs.