Promotion of Improved Productivity

Promotion for Digital Transformation (DX) and Reinforcement of the Organizational System

We began DX activities related to product and business process re-engineering in January 2021 to enhance and optimize our operations concerning important material issues. We are introducing a new enterprise system across the Group with the aim of using global integrated information and the improvement of business efficiency, and we have completed the implementation of this system at our headquarters and in some of our manufacturing sites and overseas subsidiaries. Furthermore, we have successfully completed a project involving several hundred cases across the entire Group and have entered a new phase where all employees are engaged in promoting business process re-engineering through DX activities.

In our products, we will solve high-level challenges by continuously applying the processes of (1) Recognition (sensing and monitoring), (2) Analysis and prediction, (3) Control and (4) Learning and evolution (autonomous). We will apply these processes in various contexts, from development to mass production, all with the goal of enhancing customer value. In addition to this, we are implementing over 30 initiatives across the entire Group and will continue to advance these initiatives while flexibly responding to changes in the market environment and management strategies.

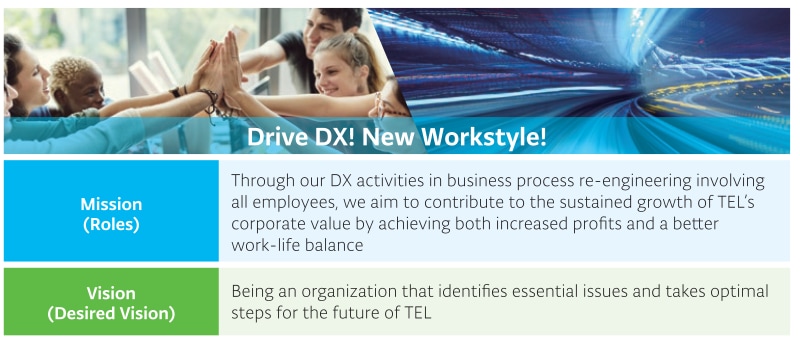

In our business process re-engineering efforts, we aim to enhance capital efficiency across all operations and promote DX activities involving all employees. In the future, promoting DX in business process re-engineering, along with productivity enhancements, will be essential to outperform a market expected to continue growing. While striving for efficiency through these efforts and transitioning to a new business model, we will contribute to the sustainable enhancement of our corporate value while achieving both increased profits and a better work-life balance for our employees.

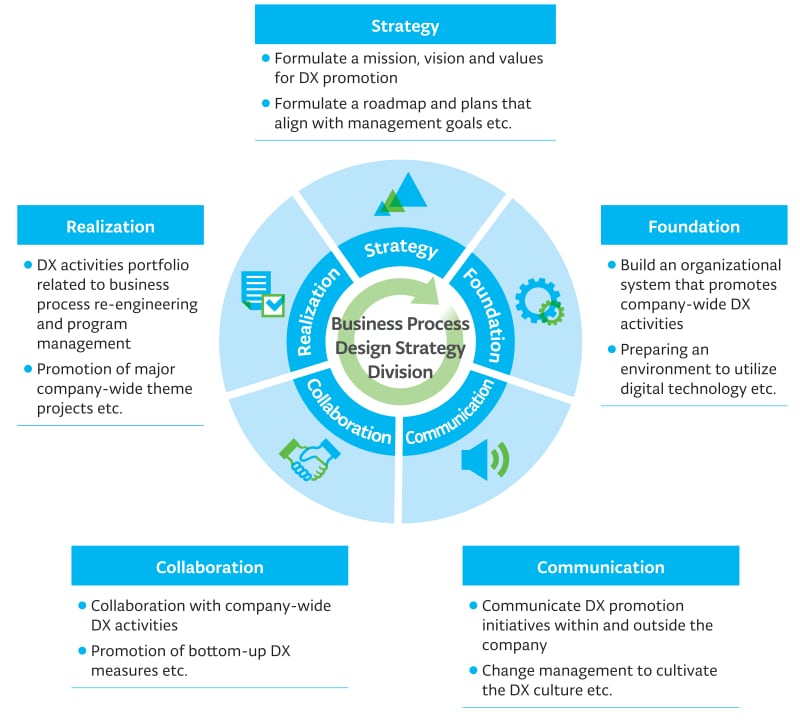

We have also established the Business Process Design Strategy Division as one of our key organizational units while integrating and reorganizing our IT departments in headquarters and across the entire Group. This initiative aims to create a system that quickly and seamlessly aligns the business and IT department to further advance DX. Through this effort, we strengthen our global governance and enhance the effectiveness of our DX promotion framework.

Effective Strategies for Driving Business Process Re-engineering through DX

Our DX initiative is crucial as it seeks to sustainably enhance corporate value while also increasing profits and enhancing work-life balance by enabling all our employees to engage in data-driven business practices. The Business Process Design Strategy Division is formulating a new mission, vision, and values to promote DX and is accelerating initiatives based on specific goals.

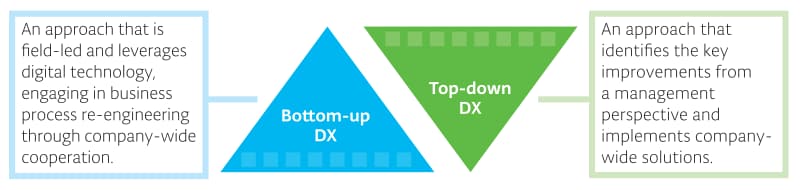

Our DX activities in business process re-engineering encompass both top-down and bottom-up approaches. Top-down DX involves identifying key improvements from a management perspective and addressing them collaboratively across the entire Group, treating each case as a project. On the other hand, field-led bottom-up DX engages in business process re-engineering through cooperation across the company while leveraging digital technology. By advancing initiatives with both top-down and bottom-up DX, we aim to proactively and sustainably achieve business process re-engineering through DX at both the management level and in the field.

In these initiatives, it is essential for everyone from management to field employees, to continue embodying the TEL Values, which represent both the principles we aim to pass on to the future and our code of conduct. Amid such a backdrop, the Business Process Design Strategy Division serves as a key driver in advancing our business process re-engineering by leading efforts to build an ecosystem. These efforts include developing a roadmap and plans that align with management goals, creating an environment that leverages digital technologies such as generative AI, civic development and human resources development, and implementing change management to cultivate a DX culture.

Building an Ecosystem that Supports Sustainable Growth

Specific Initiatives

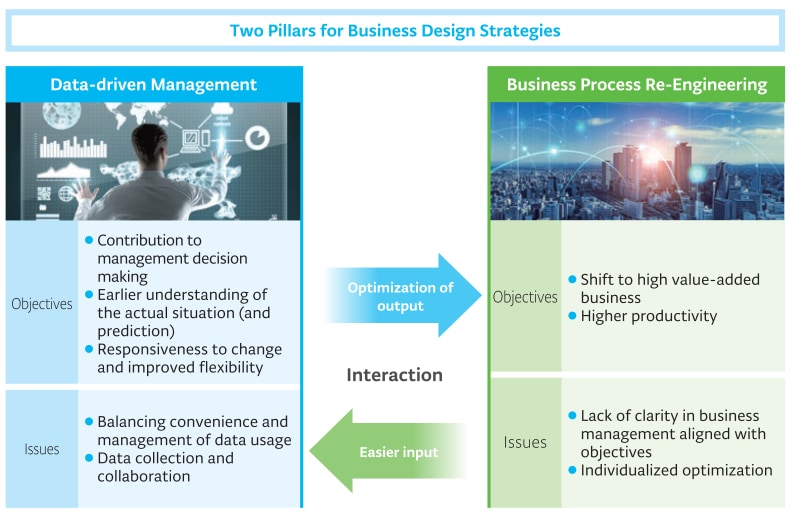

Up to now, the focus has been on local optimization of business process re-engineering based on siloed systems and data usage specific to each site and division. However, we are currently identifying issues from the perspective of factors such as increased man-hours and investment efficiency, and are striving to achieve Group-wide and integrated business process re-engineering. Specifically, we are promoting DX in business process re-engineering throughout the Group, with data-driven management and business process re-engineering as the two pillars. Additionally, we are accelerating initiatives aimed at creating synergy through mutual collaboration.

In data-driven management, we are building quick and accurate decision-making processes by creating a data platform for the entire Group and setting KPIs based on roles and functions.

In business process re-engineering, we aim to realize optimal business processes that leverage data technology while efficiently supplying the necessary data for data-driven management and identifying business issues based on visible data.

Continuous Improvement of Business Operations

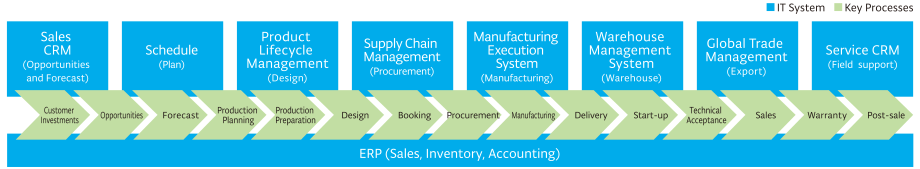

We are implementing a new enterprise system (ERP*) to further improve productivity and quality. The purpose of the system is to significantly improve operational efficiency, make management decisions that respond quickly to changes and create new value by utilizing globally integrated information with an eye toward overall digital transformation.

In addition to the headquarters, where the system has already been implemented, we first completed the implementation of this system at overseas subsidiaries and manufacturing sites in Japan in fiscal year 2024. Going forward, we will make maximum use of the knowledge we have gained through the process so far, and will proceed with the implementation of the system to subsequent sites. In addition, we will work with our partner companies to realize a globally integrated system by developing functions and others to improve operational efficiency and further enhance system performance.

Overview of the New Enterprise System

ERP: Enterprise Resource Planning. A system that integrates the core business operations of an enterprise, such as accounting, personnel, production, logistics and sales, for better efficiency and centralized information.

World-class Manufacturing Operations

Production Innovation through Smart Manufacturing

We constantly strive to innovate in production and improve product quality and profitability at manufacturing sites. We engage in the development of world-class manufacturing operations through the use of our knowledge and the data we have accumulated over many years.

At Tokyo Electron Miyagi, we are conducting verifications for the building of efficient manufacturing lines in preparation for the completion of the new production building in the summer of 2027. Specifically, we make full use of digital technologies and automated technologies, and building Smart Manufacturing Lines when implementing Manufacturing Process Architecture*¹ to further strengthen our ability to respond to customer needs and increase our competitiveness in the market to consistently manufacture high quality products with consistent quality.

Furthermore, building Smart Product Architecture*² in the manufacturing process and the administrative and indirect support processes enables the planning of an operational flow that reduces the lead time from development to mass production. In this way, we aim to save labor and automate routine operations for dramatic improvements in productivity.

Automation of docking process for each module

Manufacturing Process Architecture: Standardization and efficiency in the manufacturing process

Smart Product Architecture: Operation streamlining in related divisions other than manufacturing processes, such as production capacity management,

production planning, customer specification design and procurement

Initiatives to One-touch Start-up

With the aim of shortening the start-up period for equipment at customers’ sites and ensuring safety and quality, we are promoting continued improvement activities to realize “One-touch Start-up.” By simplifying installation and utility connection work and developing measurement and control technologies, we strive to improve the quality of work, and reduce accidents caused by human-error and prevent operational mistakes in addition to shortening the start-up period. Furthermore, we are working on the research and development of technology for the automation of processing performance tuning after the start-up of the equipment to promptly deliver high-quality equipment to customers.

For engineers responsible for the actual start-up of the equipment, we are aiming for further quality improvement in the installation and start-up through the use of 3D models of the equipment and the implementation of global training programs utilizing VR technology.

Training scene utilizing 3D model of the equipment

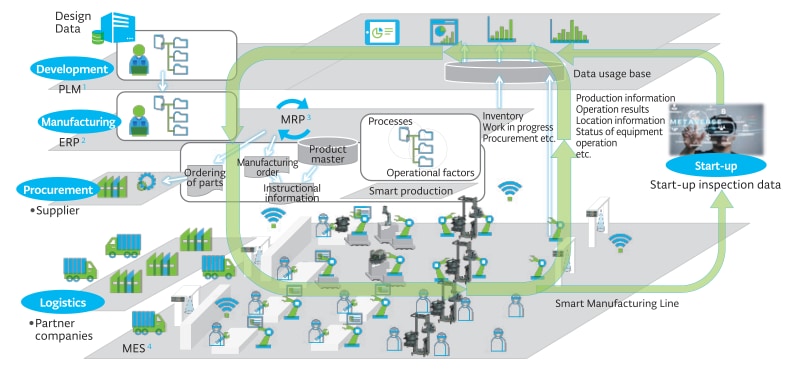

Initiatives for the Implementation of Smart Technology (Data Solutions)

We strive to build superior production capabilities that enable optimal decision-making and immediate action through the cooperation and digitization of all production-related data in real time for efficient production at each manufacturing site. By expanding the sensing functions of the manufacturing sites and using that data, we aim to manufacture high quality equipment by realizing appropriate and flexible production plans and the operation of efficient manufacturing lines.

Innovative Production Capabilities by Digital Transformation

PLM: Product Lifecycle Management

ERP: Enterprise Resource Planning

MRP: Material Resource Planning

MES: Manufacturing Execution System