- Semiconductor Technology Now

Scientist Interview

Critical partnership between corporations and research institutes

Telescope Magazine: I hear your lab is working on joint development of MEMS technologies with private corporations. Is that correct?

Masayoshi Esashi: Yes, and the lab's relationship with the industry is one of the most productive in Japan, I'm proud to say. Nowadays, Japanese semiconductor manufacturers are closing one fab after another, and they are finding it increasingly difficult to conduct R&D on their own.

With existing semiconductor production technology, it is easy to make millions of chips. However, medical MEMS devices are application-specific, and there are a great many diseases for which separate devices need to be developed. Clinical demand for such devices is often no more than 1,000 units per application, so it does not make commercial sense to produce these devices separately using dedicated production lines.

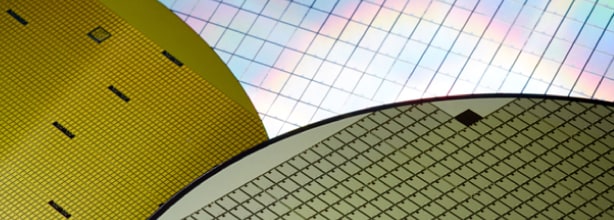

There is a possible solution to this problem: recently, 16 companies in mutually exclusive fields (including Ricoh, Toyota, Toppan Technical Design Center, Furukawa Electric, and Denso) have teamed up to produce different kinds of devices on a shared 200 mm silicon wafer, lowering the production cost compared to when the devices are produced separately. Semiconductor technologies have advanced so much that the "economy of small volume production" is becoming a new challenge.

There is a possible solution to this problem: recently, 16 companies in mutually exclusive fields (including Ricoh, Toyota, Toppan Technical Design Center, Furukawa Electric, and Denso) have teamed up to produce different kinds of devices on a shared 200 mm silicon wafer, lowering the production cost compared to when the devices are produced separately. Semiconductor technologies have advanced so much that the "economy of small volume production" is becoming a new challenge.

My lab offers a service called "hands-on-access fab" (www.mu-sic.tohoku.ac.jp/coin_e/), which lends assorted prototyping equipment in the lab (donated by semiconductor technology firms) for hourly fees to any interested firms. Tech-savvy businesses without any facilities can send their staff here to build prototypes, significantly reducing development cost and associated risks. The number of user firms is steadily growing, currently standing at 100 or so.

In 2001, we helped to establish MEMS Core Co., Ltd. with Mr. Koji Homma as president, with the purpose of undertaking technology development on behalf of client firms. Mr. Homma has a track record of developing semiconductor fab equipment as a representative of the Chemitronics Group. In the field of medical devices, MEMSAS, Inc. was established in 2008, mainly by Professor Yoichi Haga at Tohoku University's Graduate School of Biomedical Engineering. As clinical trials of medical equipment can only be performed by business organizations, MEMSAS was created for the purpose of testing and commercializing promising technologies, including the aforementioned active catheters and ultra-thin optical fiber pressure sensors for measuring the intravascular pressure.

In addition to Japanese businesses, we are also building partnerships with overseas entities. We signed a partnership agreement with Germany's Fraunhofer-Gesellschaft in 2005 and have been hosting the Fraunhofer in Sendai symposium every year. About five researchers from Fraunhofer-Gesellschaft are conducting joint research at Tohoku University's labs at any given time, and this year the Advanced Institute for Materials Research (AIMR) with which I serve is establishing a project center to conduct joint research. In June this year, Belgian international research institute Imec and Tohoku University became strategic partners, organizing seminars and embarking on joint studies. Stanford University in California and the École Polytechnique Fédérale de Lausanne (EPFL) in Switzerland are also strategic partners of Tohoku University.

Telescope Magazine: So, your view is that cooperation with businesses and other organizations is essential.

Masayoshi Esashi: Nowadays, the Japanese seem to be losing the knack for working together as a group. Japanese companies used to practice lifetime employment, and they also had some other characteristics that made them excellent corporate entities that were once the envy of overseas rivals. The advancement of globalization was a game changer, however, and forming business alliances is becoming the new norm.

Unfortunately, many major Japanese companies are too short-sighted to see it that way, and they haven't done much to cultivate cooperation with universities, either. I suspect those were among the reasons why Japanese companies have been losing their edge. I know our lab can contribute to the Japanese industries only so much, but if our endeavors could inspire others to implement similar collaborative projects, that might give quite an impetus to change the status quo.

Telescope Magazine: MEMS requires intricate customization and craftsman-like attention to detail, so it may be an ideal area for Japanese companies to exercise their strengths.

Masayoshi Esashi: It is true that semiconductor manufacturing requires huge capital investment to build plants, and universities do not have much of a role to play in that area.

MEMS, in contrast, is still an emerging field, and universities have a lot to contribute in this area. Examples include designing a system for producing large varieties of devices in small batches, making diverse key technologies widely available, and giving advice on forming alliances. Today, MEMS is at a place where semiconductors were at their inception.

Telescope Magazine: How do you think MEMS will influence the future of medicine?

Masayoshi Esashi: Medical treatment technologies are moving in the direction of personalized or tailor-made medicine. Low-cost sequencing of human genomes is a priority, and producing partial organs can also be an interim goal in regenerative medicine. MEMS has the potential of helping produce nanostructures that are essential to these efforts.

Also, MEMS will naturally continue to complement conventional electronic medical devices by enhancing the functions of catheters, endoscopes, etc., or by providing implanted devices such as stimulus electrodes. If the aforementioned disposable immunosensors become commercially available, that will enable test results to be sent from home to doctors at hospitals, helping them diagnose diseases more quickly and possibly lowering the medical cost as well.

|

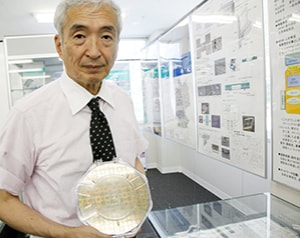

Profile

Masayoshi Esashi

Born on January 30, 1949, Masayoshi Esashi graduated from the Department of Electronic Engineering, Faculty of Engineering, Tohoku University in 1971 and completed doctorate program at the university's graduate school in 1976. He became an assistant professor at the university's Faculty of Engineering the same year, assistant professor in 1981, and professor in 1990. He is currently with the university's World Premier International Research Center - Advanced Institute for Materials Research (WPI-AIMR), serving as the director of Micro System Integration Center (μSIC). He has been president of MEMS Park Consortium since 2004, and chairman of the Japan Society of Next Generation Sensor Technology (JASST) since 2010. His research interests include semiconductor sensors, microsystems, and microelectromechanical systems (MEMS).

Books authored/co-authored by Masayoshi Esashi (in Japanese): Fundamentals of Semiconductor Integrated Circuit Design (Baifukan Co., Ltd., 1981), Electronic Information Circuits I, II (Shokodo Co., Ltd., 1989), MEMS for Beginners (Morikita Publishing Co., Ltd., 2011), etc.

Honors: Shiju-hosho (medal of honor with purple ribbon) in 2006, etc.

http://www.mems.mech.tohoku.ac.jp/index_e.html

Writer

Tatsuya Yamaji

Born in 1970, Yamaji worked as a magazine editor before going freelance as writer/editor. His areas of expertise include IT, science, and the environment. Books in Japanese by Yamaji include The Advent of the Inkjet Age (with a coauthor), Japanese Eco Technology Changes the World, and Dangen (with a coauthor)

Twitter account: @Tats_y