- Semiconductor Technology Now

Scientist Interview

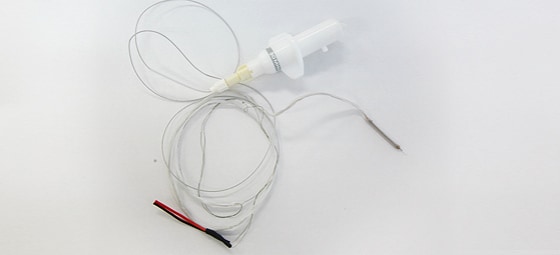

Active catheters allow flexible remote control of MEMS devices

Telescope Magazine: What exactly are active catheters?

Masayoshi Esashi: Catheters are medical devices inserted in the body to perform tests and treatments. In a cardiovascular procedure, for instance, a catheter is inserted from the patient's thigh and advanced through the vein to the heart, so a guide wire and microdevices can reach the region of interest. Conventional catheters are difficult to guide through the inside of twisted veins, which could easily rupture if pushed too hard.

Active catheters that we've developed are made of a shape-memory alloy, and the degrees of their bends can be controlled by applying electricity. This flexibility enables some tests and treatments which couldn't be performed before.

For a device to qualify as medical equipment, it is not enough to be just theoretically functional. It has to be reliably operational, safe to use, and inexpensive to manufacture.

Take active catheters, for example. One technique we used was to coat the entire catheter with a resin and partially ablate the resin with laser where electrical contacts needed to be made. By this means, we selectively plated the exposed areas with metal and simplified wiring. Another technique we used was to build a tube of super elastic alloy, turn it into a spinal-column-shaped spring by laser micromachining, and cover it with an outer tube made of silicon rubber. When the rubber tube is filled with liquid and then suctioned, the tip of the rubber closes and serves as a valve. When the outer tube is suctioned further, the spine-shaped inner tube is bowed, bending the entire tube with it. This catheter can also be used as a tube for injecting contrast medium and other liquids. The production processes do not require delicate wiring and machining, and is therefore economical to implement.

|

Telescope Magazine: So, operator-friendliness and production cost are also important factors in developing medical MEMS.

Masayoshi Esashi: We have also developed such minimally invasive devices as an ultrasound forward-looking imager and an optical scanning endoscope.

Ordinary endoscopes illuminate the object with light for observation. The method works fine when examining the stomach or the lungs, but is unsuitable for observing the inside of blood vessels where the blood obstructs light-unless you flush out the blood with water beforehand, which is possible but impractical. So we built an ultrasound forward-looking imager. It is a catheter with a small ultrasonic echo scanner attached to its tip. Unlike similar existing devices that send ultrasonic pulses laterally to scan sections of a blood vessel, this device directs ultrasonic pulses forward to check if there is any blockage ahead, and to finely adjust the catheter's movement.

The other device-the optical scanning endoscope-was developed to enable doctors to perform examination and treatment at the same time. When the scanned image shows a cancerous growth on screen, for example, you can move a cursor there and lock onto it to implement laser ablation treatment. Since a human body is constantly in motion due to respiration and other activities, keeping a lock on the target area requires sophisticated image recognition algorithms similar to those used in guided missiles. That's how this system ensures that only the diseased spots are attacked and not the healthy tissues.

In the future, perhaps a doctor on a passenger aircraft may be able to perform an emergency endoscopic surgery on a sick passenger while airborne, provided that the doctor has such a device at hand.

|

Telescope Magazine: About five years ago, electronic industry journals used to predict that many medical MEMS devices would be in professional use by 2012 or so, but it seems the prediction hasn't come true yet. What's your take on that?

Masayoshi Esashi: Well, I'd say both MEMS and its medical applications have made significant advancements, at least in terms of technology. The trouble with Japan seems to be that the interactive cycle of R&D and commercialization is not running very smoothly.

The national government can encourage researchers to work on certain themes through targeted budget allocation, but that alone is never enough. The lab-produced devices must be promising enough for businesses to invest in, which ensures that many rounds of clinical trials are conducted to further refine the technology. Keeping this virtuous cycle running is essential, and we are striving to build a framework for that at Tohoku University.