- Semiconductor Technology Now

Technology

Costly products do not sell not matter how good they are

The H-IIA and H-IIB rockets have thus far established high reliability. However, their track records reveal some issues that need to be addressed.

The greatest concern is the high cost involved. An H-IIA rocket costs roughly 10 billion yen per launch, though actual figures vary for each vehicle. Twenty-two H-IIA rockets were successfully launched so far, and the main payload for every one of them was a satellite funded by the Japanese government. (The 21st vehicle carried a Korean satellite as well, but the main payload also included a Japanese satellite.)

|

Reasonable pricing is vital to winning orders for satellites in the private-sector market. The Falcon 9 rocket developed by SpaceX (a U.S. space venture) has a low Earth orbit (LEO) launch capacity of about 13 tons, which is on a par with H-IIA's. However, launching a Falcon 9 costs only $54 million (about 5.1 billion yen at 94 yen to the dollar), which is about half the cost for H-IIA. Although the track record of Falcon 9's launches is still too short, its price tag is certainly very attractive to customers.

Although H-IIA was developed by the government, its launch business was transferred to Mitsubishi Heavy Industries in 2007 with the launch of the 13th vehicle. The shift to the private sector was partly motivated by a hope for substantial cost reduction. However, the scope of cost reduction would be limited if the existing H-IIA design were to be retained. To achieve drastic cost-cutting, development of a radically new rocket design was imperative.

That is why the next-generation H-X rocket is currently on the drawing board.*3

The launch business cannot be maintained by simply satisfying the demand from the government, so winning orders from the private sector is essential. In Japan, for instance, the government needs to launch maybe one to three satellites per year, and the number changes from year to year. To improve profitability, the rocket production line mustn't be kept idle. Ideally, orders won in the private sector should take up any slack in production and maintain the pace of about four rockets a year.

That requires H-X to be far less costly than its predecessors while attaining high reliability.

Although the development of H-X hasn't started yet, JAXA has already been conducting a number of theoretical studies. Development of a new large rocket is a long-term project. The future shape of H-X will be determined through national-level discussions. In the meantime, it is vital to study various candidate technologies, if only to reduce the risk of failed development.

|

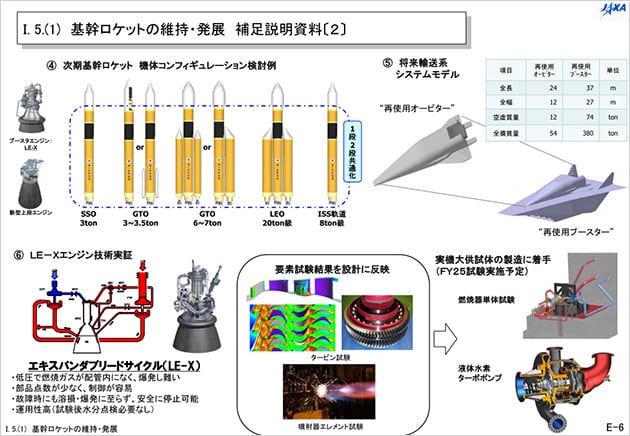

The figure above is a concept of the H-X rocket found in the document JAXA submitted to the 37th JAXA Subcommittee meeting of the Ministry of Education, Culture, Sports, Science and Technology (MEXT). This concept is just a sample and does not necessarily dictate the framework of H-X, but the paper does suggest that the concept answers a broad range of launch needs, as the first and second stages are shared by different models and boosters appear to be added rather flexibly.

The key to the development of any rocket is the engine. As mentioned before, large liquid-fuel engines are very complex in their structures. Development of a new engine takes a long time, which in turn delays the development of the carrier rocket.

Any change in engine specifications also affects the overall rocket design. For this reason, JAXA judged it was too risky to develop the carrier rocket and the engine simultaneously, and chose instead to work on the engine first. Accordingly, technology evaluation of the next-generation first-stage engine (LE-X) has already started.